An Aluminum Waterproof Box: A Simple Invention That Changes Industries

When planning a project, you should think about the smallest details. One tiny neglect may cost you a lot of effort and money. An important thing to think about is protection.

Whether you’re fashioning an environment monitoring tool or a piece of security equipment, its enclosure determines its durability.

How to protect electronics from harsh weather conditions, moisture, UV exposure, temperatures?

If only there was an enclosure of some kind that you could order for your device, a waterproof box of some kind. Well, there is such a thing.

Nowadays, you can order a custom junction box made from high-quality aluminum. It will neatly fit the form of your project, protect it, and make it look fabulous.

Why Choose an Aluminum Waterproof Case

There are lots of case materials to choose from, including aluminum and plastic. The two options are used most commonly. We’re all hands for aluminum because of the wide range of benefits it provides.

Benefits of Aluminum Enclosures

“Metals corrode, how can they protect machinery so well?”

Not aluminum. Alloys containing it are naturally resistant to corrosion. They are also very durable and have a number of other advantages. Let’s get into them:

- High-temperature resistance: High temperatures won’t let your device catch fire due to a resistance enclosure. However, if you’re working with temperature-sensitive devices, it’s better to choose a non-conductive case.

- High impact strength: Damage control is high, which makes it easy to transport such units.

- Lightweight: Aluminum is sturdy in alloys yet lightweight, which makes it a better metal choice than steel.

- Natural RFI and EMF shield: Radiofrequency interference and electromagnetic frequency won’t damage the work of your device due to such encasing. This is great for projects where minimal interference is required.

- Flame protection: In case of a fire, aluminum-protected gadgets will be saved due to high-temperature resistance and flame protection.

- UV resistance: We all know that UV radiation may damage not only our skin but our electronics. An aluminum case will help you avoid device problems over time.

- Natural corrosion resistance: Aluminum alloys don’t rust, which is why you should definitely have them on the list of metals to use for encasing. This also means that moisture won’t damage the box.

- Recyclability: Aluminum scrap is easily recycled and always in demand. This is great news both for you and the environment. You don’t get to throw away useful materials once their job is done, and they won’t appear in landfills later on.

- Deformation resistance: Aluminum alloys resist swelling and other deformities, which makes them even more long-lasting.

- Durability: The overall durability is impressive. While aluminum itself is considered a softer material, in alloys it’s the true hero of positive qualities.

- Easily painted and coated: You can order a powder coat or an anodized finish to further improve the protective characteristics of the case.

This is quite a list. But where to get a high-quality aluminum enclosure? We have an idea.

The Best IP68 Box Manufacturer

Behind every high-quality outdoor electrical box stands a powerful manufacturer with several teams because every stage needs a professional look and control.

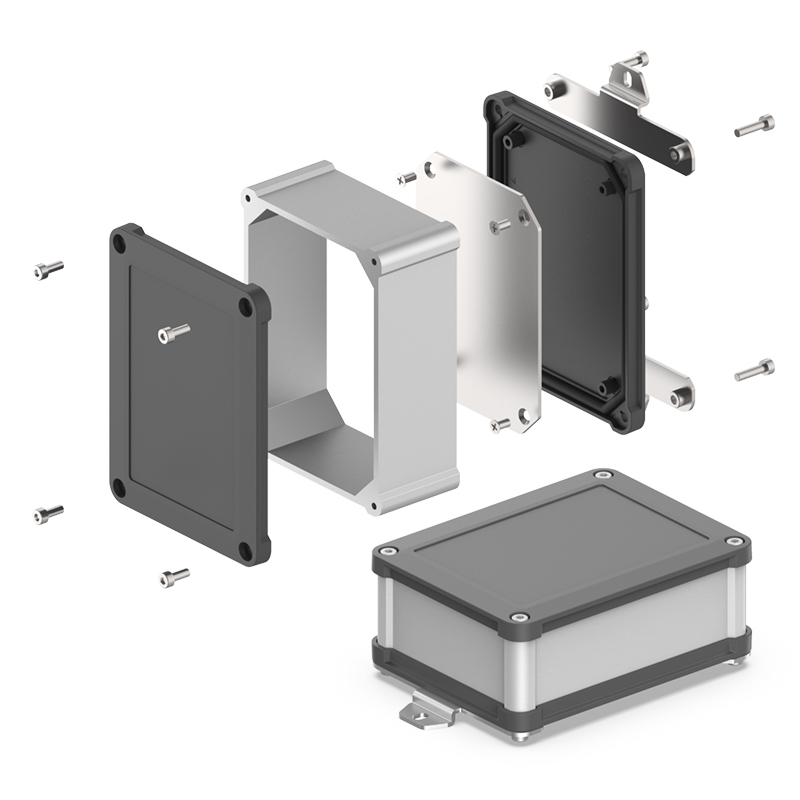

The design of the box determines the looks and how ergonomic the IP68 case will look. The engineering team is responsible for making the design come true. Other teams decide on the best solutions for materials, finishes, etc.

So, the company you choose to work with is just as important as the box you’re going to get.

And we’re here to talk about one of the best manufacturers located in Foshan, China, the almighty aluminum center of the country.

Guangdong Yonggu Electronics Machinery Technology Co., Ltd

Guangdong Yonggu Electronics Machinery Technology Co., Ltd, or briefly YG Enclosure as their website name states, is a professional manufacturer specializing in aluminum enclosures for all kinds of projects.

This business will create a perfect Raspberry Pi case for you in a short time. Within more than 15 years of experience, they have worked with various industries and their designs are used all around the world for over 8 years.

Some niches YG Enclosure works with are:

- Digital communication products;

- Environment monitoring tools;

- Security equipment;

- Rail transit;

- Outdoor electronics, and many more.

These guys protect your protection (if we’re talking about security equipment) with custom design and state-of-the-art technologies.

The company owns 14 design patents created by a team of structural and appearance designers and top engineers in the field.

You can order any custom design and they will provide you with:

- A CAD document;

- 3D files;

- CDR vector diagrams.

- Solidworks or STEP drawings;

- PDF format;

- and they also accept samples from customers

If you need mass production for your product line, this isn’t a problem either. YG Enclosures is ready to mass-produce and provide high-quality cases for your projects. They have 14 production lines and around 5,000 sq.m of the workshop.

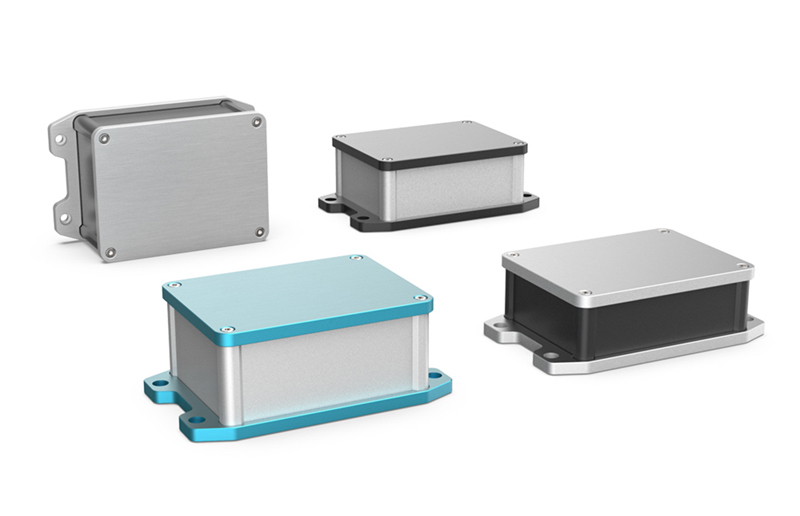

You can also choose a custom finish:

- Anodizing;

- Painting;

- Powder coating.

To match your brand, choose any color of the finish, and you’ll get just the hue you wanted! You can add as many as 9 colors. If you need a custom drawing, they can do it too in one of the following ways:

- Silk screen printing: Choose any color for your logo.

- Laser engraving: This drawing will never fade and will add a unique touch to your product.

So, adding a logo to the case won’t be a problem.

Anodizing (colorful examples below) is an extremely beneficial finish as it strengthens the surface hardness and corrosion resistance of the material.

Company Factories

The company has 3 factories in total, with 1 more due next year:

- Samples processing and warehouse;

- Batch production factory;

- Anodizing factory.

All of these facilities allow for better quality control of every sample manufactured by the company. The best al6063 materials are used, along with decades of professional experience.

Anodizing as One of the Highlights of YG Enclosure

Two types of anodizing are available to you:

- Sandblasting.

- Brushed anodizing.

For the former, YG Enclosure has all common sizes (80#/120#, 150#, 180#, etc.), as well as the most demanded styles, including:

- Glass sand;

- Iron sand;

- Emery sand;

- Ceramic sand;

- Zirconium sand, etc.

The dyes are plenty as well. All are of the best Japanese quality.

Why is anodizing so useful? It strengthens aluminum to its maximum capabilities. Every sample becomes times more durable and corrosion-resistant. The finish provided by YG Enclosure withstands temperatures up to 200C and provides level #8 UV protection!

If you’d like, a team of professionals working for the company will help you make the salt-spray testing free of charge!

To Sum Up

Aluminum is an amazing material for protective enclosures. It’s durable, highly resistant to damage, weather conditions, high temperatures, and corrosion. It’s also recyclable and easily coated, which provides a ton of benefits.

But the most important thing is to choose a company that will design an enclosure for your project that will fit and last for ages. We know such a company, it’s Guangdong Yonggu Electronics Machinery Technology or YG Enclosure. You can visit their website to see the scope of work the teams do to provide full protection for electronics of any kind!