Create a self-service car project using STONE Serial Screen and ESP32

This article details the process of making a self-service car project by utilizing STONE Serial Screen and ESP32.

In particular, we will be discussing the following:

- Tire inflation

- Vacuum dusting

- Smoke disinfection

- Fuel additive

This project allows users to perform at least 4 types of cleaning on their cars as well as other self-service.

STONE Technologies provided the Smart TFT LCD module STVA080W-01 and the GUI design system STONE DESIGNER to make the device more user-friendly and aesthetically pleasing.

The main controller of the device is ESP32 and uses more than 20 sensors, motors and microswitches.

The following section will focus on the GUI development of the TFT LCD module of STONE as a DEMO.

First of all, STVA080W-01 is an 800*600 resolution Advanced type serial screen with 4-wire resistive touch panel, brightness up to 900cd/m2, viewing area 162*121.5mm, working temperature -20~70 degrees Celsius, can adapt to outdoor use.

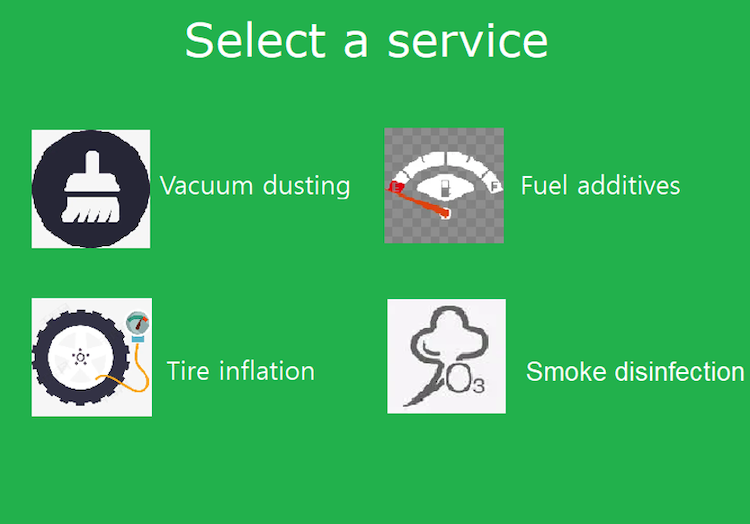

In the serial touch screen, in addition to the customized logo, the main menu in Figure 1 is the graphic plus text selection buttons for 4 cleaning or supplementary service items.

As this machine adopts coin-operated charging method, the first level sub-menu after entering each service will give the charging guide of this service to guide customers to coin first and then enjoy the service.

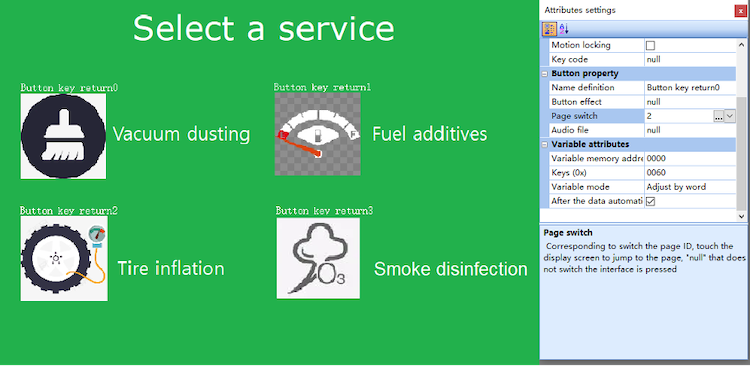

Check “Return pressed key value” in the menu of Stone Designer (GUI design software) under Touch Configuration (M), or click the Return Value button tool in the figure to create a return value button at the desired location, and press Figure 2: Fill in the variable address and key return value at the marker, and check the box to automatically upload the return value when pressed.

The four return value button variable addresses are 0x0000, 0X0001, 0X0002, 0X0003, and the key return values are 0x0060, 0x0061, 0x0062, 0x0063. The page switch should be set accordingly to the submenu of the corresponding function.

After monitoring by the serial assistant, the return value of the serial assistant for each function key is accepted as follows:

A5 5A 06 83 00 00 01 00 60

A5 5A 06 83 00 01 01 00 61

A5 5A 06 83 00 02 01 00 62

A5 5A 06 83 00 03 01 00 63

The device host controller will decode the key return values and process the corresponding submenu page data.

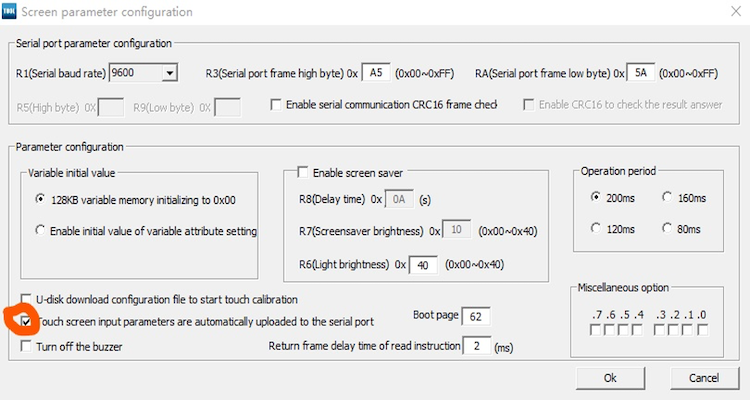

If there is no key return value, remember to check and tick the red marked place in Figure 3.

Location: Main Menu – “Tool (T) – “Screen Configuration.

Press aspirator to enter the vacuum vacuum function sub-menu, display interface as Figure 4, which has a coin to get the vacuum dusting hours reminder, there is a return to the main menu button, work, pause button, when the coin, will promptly display the purchased hours, work will show the remaining hours countdown.

Also can adjust the vacuum suction power, the default can be 1 level, work can be adjusted according to the need through the up and down button to Level 2, level 3, and even the highest level 5.

The higher the level, the greater the suction power. Of course, the work will automatically stop when the time runs out, then you can coin again, or you can go back and quit. Set 1 coin to get 5min time, more coins to get more time, and so on.

See Figure 5, also in the Stone Designer GUI design software menu Touch Cinfiguration (M), select “Return pressed key value”, or click the return value button tool in the figure, in the start, pause, and Click on the Return Value button tool in the figure to create three return value buttons in the start, pause, and return to main menu locations, and check the box to automatically upload the return value when pressed.

Here 3 return value button variable address are 0x000D, 0X000E, 0X000F, key return value are 0x0064, 0x0065, 0x0066. which, return to the exit key Page switch parameter set to 1, linked to the main menu interface.

Then select “Data variable” control under Variable Configuration (D) in Stone Designer menu bar, make three data variables with addresses 0x0013, 0x0018, 0x001C, set the appropriate The integer number and decimal digits are set to 0, because there are no decimals.

Next, in the corresponding position of Suction rating to do plus and minus keys, select the menu Touch Configuration (M) under the Incremental adjustment control, where the memory address of the two incremental controls are set to 0x0013, that is, the same address as the Suction rating data variable The minimum value is 1 and the maximum value is 5. See Figure 5, right column of parameters.

Each button has a return value, the main control board can know the action of HMI at any time, and give the corresponding control and regulation, feedback.

For example, when the remaining time is not 0, touch the button “START”, the auto self-service station will start the vacuum pump operation and control the output of the vacuum pump according to the suction force size set by Suction rating.

When the pause button is pressed, the air channel of the vacuum will be cut off from the outside world. When working, the remaining hours count down automatically until 0 stops.

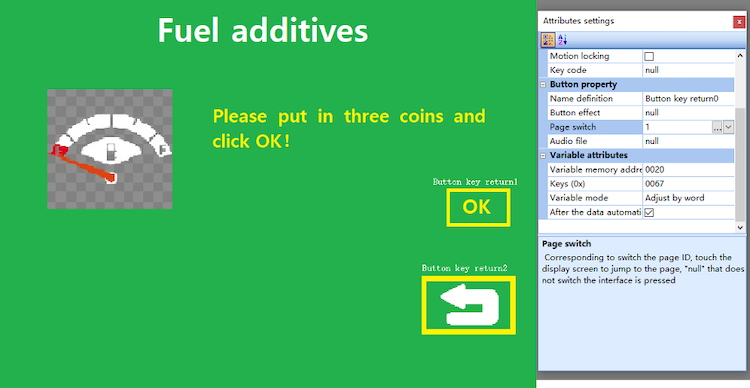

Compared to the vacuum function, the fuel additive service interface is much simpler! Here is just a prompt to put in 3 coins to buy a bottle of additive, press ok and pick up the goods in the shipping window.

There is also a button to return to the main menu interface. The memory address of the two buttons are 0x0020, 0x0021, the return values are 0x0067, 0x0068, which return to the exit button Page switch is also set to 1. See Figure 7.

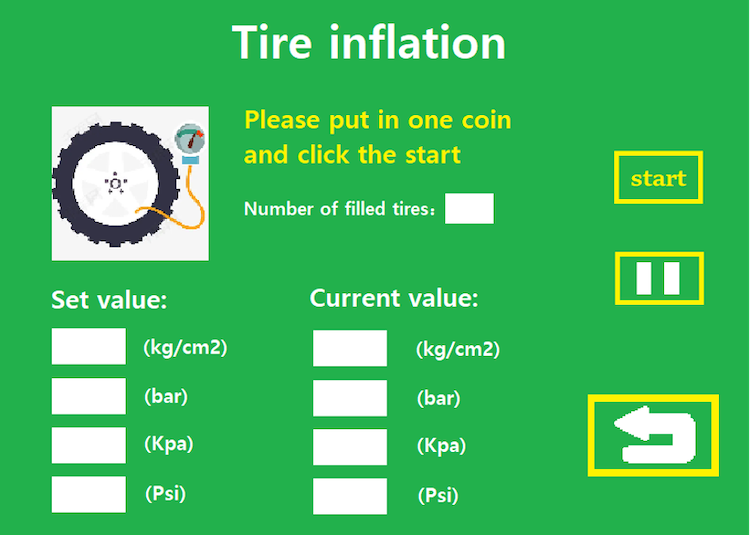

Only one coin is needed for the electric inflation service, and the interface has four air pressure units displayed simultaneously in two columns to show the set air pressure and the current air pressure respectively.

Unit conversion is automatic. When the inflation reaches the set value, the controller will pause the inflation and keep the air pressure, and count the number of tires that have been inflated.

The addresses of the three return value buttons in Figure 9 are 0x0022, 0x0023, 0x0024, and the button return values are 0x0069, 0x006A, 0x006B, respectively; the Page switch to return to the main menu button is also 1.

The nine data variables in this interface, the addresses are 0x0025, 0x0029, 0x002D, 0x0031, 0x0035, 0x0039, 0x003D, 0x0041, 0x0045; according to the use of the range, each data set a different number of decimal places, but the variable address is still stored in the integer, the display will be based on the decimal places multiplied by 0.1, 0.01 operation, pay attention to the conversion between the relationship.

Set by bar unit 2.00, then the corresponding address 0x002D initial value of 200, kg/cm2 initial value of 204, Kpa initial value of 2001, Psi initial value of 290.

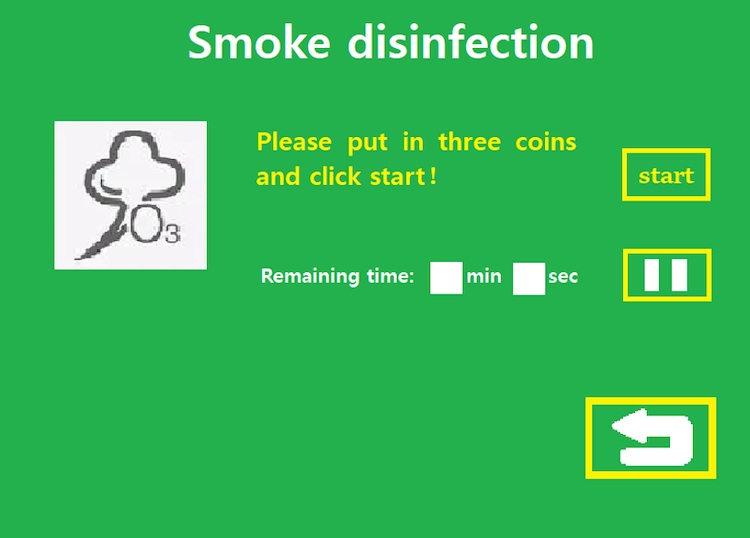

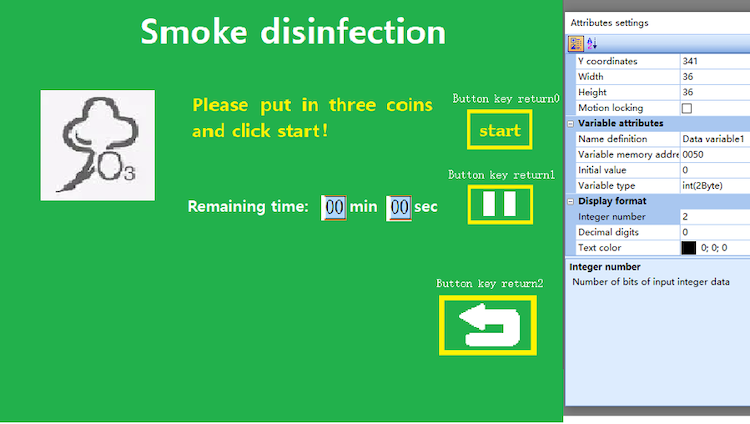

The three return value buttons in Figure 10 are the same as in Figure 8, except that the addresses are 0x0049, 0x00 and 0x004B, and the return values are 0x006C, 0x006D and 0x006E, respectively.

The Remaining time data variable has the address 0x004C for minutes and 0x0050 for seconds. This interface The minimum consumption is 3 coins, according to the purchase time, smoke disinfection is started, and can be paused in the middle, and the remaining time countdown to 0 will stop smoke generation and exit.

Controller according to the above 4 functional interface of each data, return value control address and key value for the corresponding processing, algorithm, to ensure the normal operation of the device.

—

Article contributed by Grey Ii.