Automated COVID Testing Thanks to a Tireless Robot developed by item America

The sheer scale of the COVID-19 pandemic has led to numerous innovative developments in industry to provide efficient solutions to meet the multitude of new challenges.

item America has played a part in several automation projects in the age of COVID – the manufacture of face masks and a workstation for analyzing coronavirus tests.

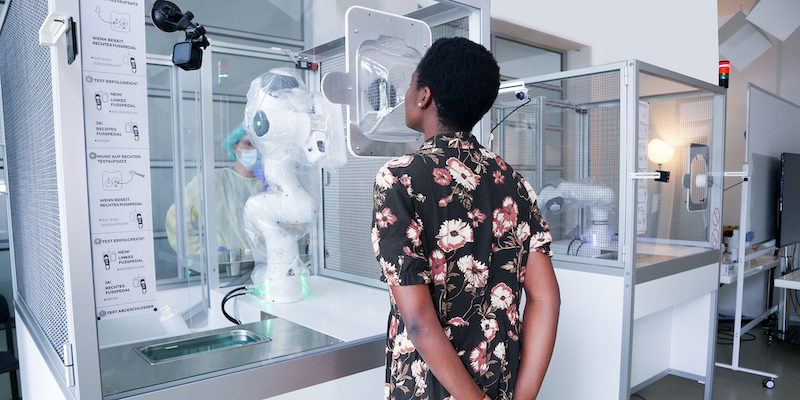

Now, item has played a role in the world’s first automated coronavirus testing station. Developed by Munich-based Franka Emika GmbH, a test station housing the “SR-NOCS” (“Swab Robot for Naso- and Oropharyngeal COVID-19 Screening”) swab robot.

Autonomously taking nose and throat swabs for analysis and/or rapid tests, the SR-NOCS reduces the risk of infection considerably while its precision and ability to operate continuously take a great deal of strain off medical personnel.

Line X from the item MB Building Kit System, which is perfect for hygiene-sensitive applications, is used for the frame of the robotic coronavirus testing station.

“I took care to make things as flush as possible so that disinfection processes work better. Profile X is used in the station because of its smaller outer radius,” says Benjamin Loinger, Industrial Designer at Franka Emika.

The profile technology also offers Loinger the greatest possible flexibility. This is a real advantage, especially for research projects, as the specific hardware and the positions of screw fixings only become clear as the project progresses.

In addition, he also appreciates that item profiles with closed grooves can be combined seamlessly with other elements such as sheet material and wood, creating a particularly high-quality look.

His colleague, solution engineer Martin Kulzer, primarily uses the aluminum profiles for tables for robots, test stands and demonstrators. He also benefits in many ways from using them.

“Of course, modular design is the big draw of item, but so are reusability and stability. Being able to fasten and move parts easily is a real advantage, particularly on demonstrators and test stands.”

Are you interested in digitalization and what the future holds for mechanical engineering? Discover the item blog here, where we’re sharing the latest innovations and ideas.