Several ways on how robotic technology can optimize efficiency in manufacturing

Wondering how robotic solutions support the manufacturing process in the contemporary world? Keep reading this article to discover several ways they do it!

Since the industrial revolution, technologies have been stably developing and seeking to satisfy the increasing demand for efficiency and top quality. In the industrial sphere, the manner of rivalry is modifying on national as well as global levels.

In factories, advanced technology use has generated novel opportunities for businesses and startups to study additional possibilities of addressing constantly changing and unique expectations.

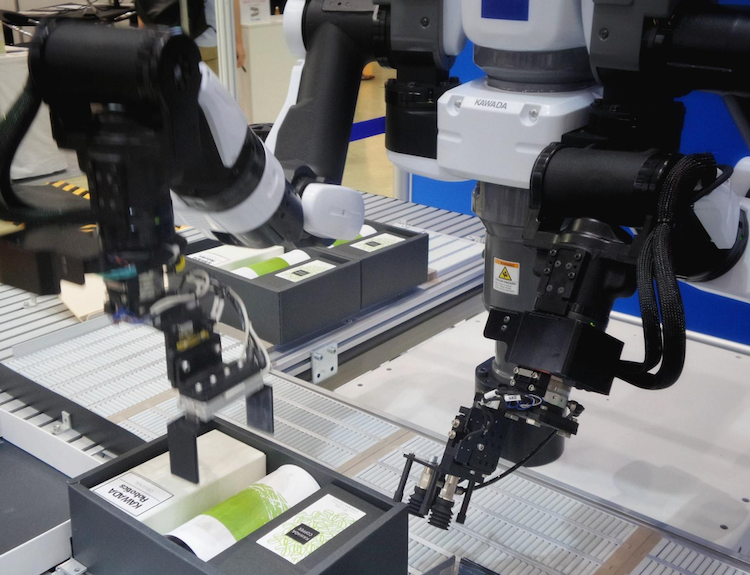

Robotic devices implemented in manufacturing execute a wide range of functions. In manufacturing, entirely autonomous robotic equipment is traditionally required for repetitive, high-scale practices where the rapidity, durability, and accuracy of a robot enable unparalleled pluses.

Another type of automation solution in the manufacturing process involves robots applied to support engineering teams with more challenging activities. The robot performs several aspects of the manufacturing such as lifting and relocating heavy compounds.

Robots are highly appreciated in the manufacturing industry due to such characteristics as predictability, reliability, accuracy, and resistance to dangerous environments. Such devices possess a variety of potential use in manufacturing as they are programmable and flexible.

The innovative sensor method ensures robots to see, hear, and feel the surrounding.

In case you want to develop a robotic solution with the above-mentioned features for your startup, it is time to search for global engineering companies like Engre.co.

Now, let’s consider several ways robotics support manufacturing in terms of productivity.

Processing Raw Material to Improve Safety

As a rule, the manufacturing process presupposes the use of different chemical materials and other radioactive components resulting in exposing employees to risk. That was a usual practice before robots started performing this activity.

The way how robotic devices execute their job in the dangerous working surrounding is truly spectacular; they successfully deal with everything from perilous chemicals to nuclear substances.

Engineering teams program robots to work with such substances and materials with enormous care. With the help of robotic solutions, while handling dangerous components, the worst scenario presupposes tech maintenance but not an employee death.

So, optimized personnel safety is one more great plus of using robotic equipment in manufacturing. Operators don’t require getting involved in risky activities anymore. Such tasks commonly include picking up heavy objects that are usually job with repetitive motion. Operators feel out of danger if those kinds of their responsibilities are executed by robots.

Moreover, robotics can support in avoiding goods damage in warehouses because they better cope with temperature-sensitive/dangerous substances/materials.

When manufacturers lose products due to damage, this involves mishandling by transit equipment or employees costing a business owner a fortune. However, this is easy to prevent if they use robots.

Multi-Purpose Implementation

Using robots in manufacturing can be extremely cost-effective not only for big corporations but for small businesses/startups because nowadays, a wide range of tools is available for the last category to enjoy the advantages of automation without the excessive costs.

Small businesses/startups can implement robotic solutions more than ever to assist with the daily routine in manufacturing as well as the supply chain.

Manufacturers can release more goods, emails, messages, and other communication with the help of robots. Apart from whether robotic solutions act as real robots or as services that imitate a robot, they are likely to deliver bigger efficiency in a shorter period.

Robots move fast and accurately, so they can deal with product components that are too tiny for human eyes or fingers. Here, robots never make mistakes. This is one of the most obvious reasons for the increasing numbers of goods developed only for robotic assembly.

There is an eclectic usage of robotic solutions in the manufacturing industry. It makes no difference whether a business owner is generating car components or developing refrigerators, engineers can program robots to design accurately to the business’s needs.

Lengthier Working Hours

As far as it is legally required that human employees should take breaks during the working day, they usually undergo various distractions that lead to a decrease in their attention spans.

On the contrary, robots can perform their responsibilities 24/7. Moreover, they work at full efficiency in such conditions. One more thing is that robots don’t require to take holidays/sick leaves or have sudden absences.

Growing Output Capacity

According to the Department of Labor statistics, robotic solutions can significantly optimize the capacity level of American employees by means of economizing on utilities, generating cleaner working environments, and even gaining their ROI during a maximum of 1 year.

Fundamentally, robotic solutions can support native enterprises rival the offshore manufacturing businesses because robots will allow reducing budgets and employee resources.

Adding Prestige

Amazing your customers by performing advanced achievements of your industry, robotic solutions are truly incredible as a marketing tool as well as cherishing your brand image.

Moreover, they can be implemented just for PR if all the benefits they have already given to you are not enough!