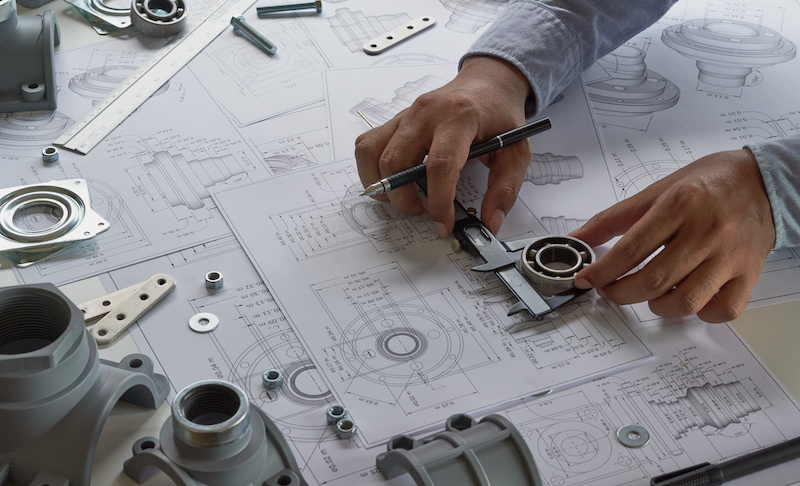

6 Engineering Tips When Designing Machinery

One of the commonly asked questions from machine designers or integrators is how they can effectively build a machine design or integrate the conversion of a machine with servomechanism advancement to meet the expected performance and needs.

Although this may be a challenging endeavor, technological advancement has made it easier to create engineering variations and unique operating processes.

When designing machinery, it would be helpful to employ several effective engineering tips even during the planning stage. It’s crucial to analyze all the possible scenarios to decrease the chances of failing and working through a demanding set of combinations and situations.

For this reason, it’s important to create a standard of machine functions and each of its axis concerning the general operation process and performance.

The following article discusses some of the engineering tips you may use when designing your machinery. Read on to get an insight.

1. Aesthetics

The appearance of your machinery is the most prominent part of the design process, and it’ll be the first thing your potential clients can notice about your product. It’s important to understand that most potential customers will look at your product’s appearance before analyzing its specs and operation process.

For instance, you may improve the machinery appearance by covering all the cable glands, giving your product a fresh, soothing look. The product’s aesthetics will play an important role in deciding whether the client will purchase your product or not.

Conduct extensive research to figure out the latest design trends in your field, as well as other industries. Understanding how customers want their products to look like should be your priority.

2. Choose Sections for Torsion Loading

Torsion can be described as the twisting point of machinery and is measured in terms of foot-pound force. It’s important to understand that the highest shear stress will occur on the surface of the shaft. For this reason, the point you choose will substantially affect the stiffness and resistance of a structure or machinery.

If possible, choose closed segments, as the stresses will be spread more evenly over the total area, allowing a greater load. On the flip side, avoid choosing open units for torsion loading. Utilize the available formula to figure out each section’s angular displacement before choosing a torsion loading point.

3. Use Force-Tolerant Materials

Components such as nylon cable grommets should have a higher tolerance to protect the crucial parts of a machine against forces that may damage or deform the design of the machinery.

During the planning phase, it’s important to consider the amount of force your machinery may withstand and how excessive force may affect its life. Any damage or permanent deformity may increase the chances of machinery failure, increasing the maintenance cost.

Another force you may consider when designing your machinery is the wear and tear force. This force may remove material from the surface when two surfaces are against each other. The removal of materials from the surface can lead to a weaker structure, and eventually, it may collapse. Utilize tips such as lubrication, increase rigidity and strength of surfaces, and increase contact surfaces to reduce wear and tear force.

4. Simplicity

When designing your machinery, ensure that it’s user-friendly. Avoid developing a piece of complicated machinery as this may demotivate potential clients. For instance, the machine’s components should be in such a state that they can be easily assembled to form the complete machine. For mass production of complicated machinery such as vehicles, electronics, etc., the concept of unit assemblies is common. As a designer, you have to make them as easy as possible.

5. Have Options

When designing your machinery, ensure you go through the concept generation process to generate several ideas. Scrutinize the generated ideas and try to settle on at least three ideas that could work. Having options ensures you cover almost all the loopholes; thus, you design efficient machinery that may meet customers’ needs and expectations.

6. Safety Consideration

Safety is another crucial engineering tip. It’s a vital part of any machinery and should be considered during the planning stage. It helps reduce risk hazards and figure out functional conditions. You may install programs to know what part of the machinery isn’t in a safe state and how this may affect the rest of the machinery. The programs may help improve your uptime while reducing wastage.

Avoid adding safety components after you’re done building the machine. This may affect the overall design and increase the time you use to design and build your machinery.

7. Takeaway

Engineering forms an integral part of any machine design and development. As discussed above, some of the tips you may utilize when designing your machinery include aesthetics, torsion loading, force-tolerance materials, simplicity, having options, and safety considerations.

When designing machinery, ensure you utilize the tips given to developing a user-friendly and efficient product.