Manufacturing Masks – Using Your Own Production Facilities

The coronavirus pandemic saw the demand for masks skyrocket. Meeting that demand meant finding solutions fast.

The demand for medical face masks has risen particularly steeply. These are not the everyday fabric or “community” masks that keen crafters around the world are now churning out.

Although such face coverings do lower the risk of the wearer passing on the coronavirus to others (source control), they fall short of the stringent requirements in medical and industrial environments, where the wearer needs to be protected from infection and/or pollutants.

Surgical masks – a type of medical face mask – provide more effective source control than community masks but still offer the wearer only limited protection.

By contrast, a respirator, or filtering face piece (FFP), without a valve provides effective source control and protects the wearer from the coronavirus, too.

Naturally, governments across the world are keen to access supplies of high-quality masks without having to rely on imports. This is where Jonas & Redmann Group GmbH comes in, a company that specializes in automating complex production processes.

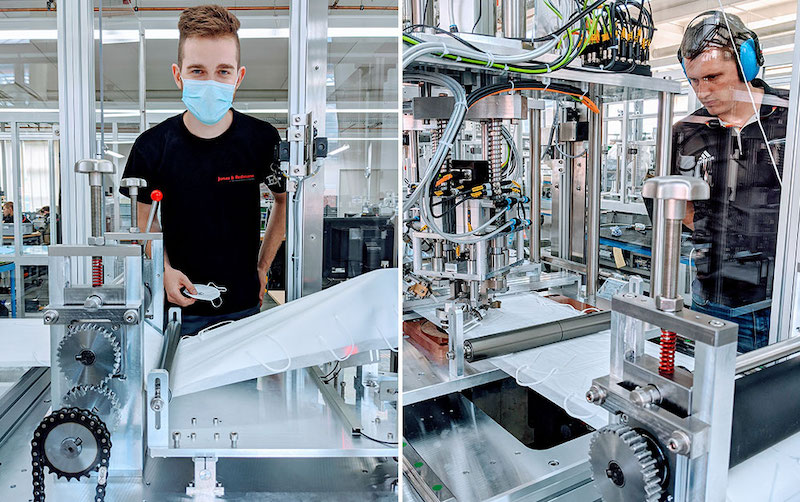

In next to no time, the specialist mechanical engineers developed production systems for manufacturing certified FFP2 masks and surgical masks.

The company is using Line XMS from item to build the enclosures for its production systems, and both machine types can be supplied in an impressively short space of time.

Fully-Automated Production Line for FFP2 Masks and Surgical Masks

Specialist mechanical engineering projects on this scale usually take around eight months to complete. However, since the basic principles of mask production are very well known, the team had a solid basis to build on.

“We looked into the general state of the art so we could improve it in very specific ways and build in our design approach. We worked fast – compressing about eight months of work into eight to ten weeks,” says René Klärs, Head of Assembly Automation at Jonas & Redmann.

The production system Jonas & Redmann Group GmbH built to manufacture FFP2 respirators without valves can turn out up to 150,000 masks per day, depending on the type being made.

To achieve this output, material is fed into the system and processed in sync. Everything is fully automated, from feeding in and applying the nose clip, shaping the mask contour and welding on the headbands (both using ultrasound) to compression, straightening the headbands, separation and stacking the masks.

A special spunbonded nonwoven fabric is incorporated into the centre of the masks and features an antistatic charge, which prevents coronavirus particles from penetrating. The second, fully automated system for manufacturing surgical masks is also designed to produce masks at high speed.

Interested in exactly how XMS profiles from item, the basic elements used to build both production lines, have simplified the process of creating automated mask production systems? Read more on the item blog here.