Grenzebach launches new conveyor technologies

Grenzebach says its new generation of conveyor technology makes it possible to further increase the availability of float glass plants.

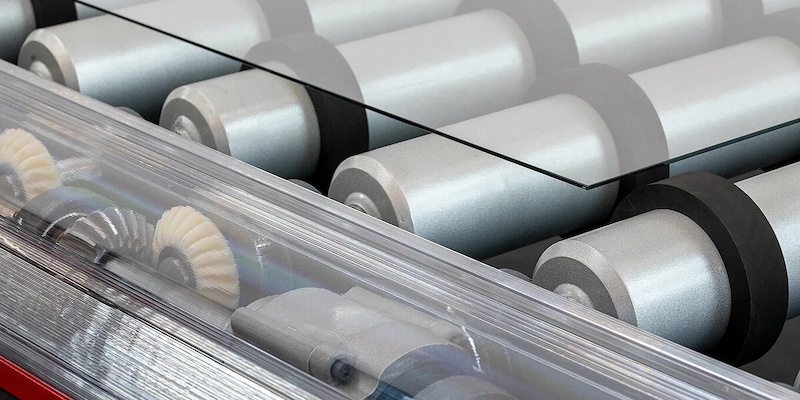

Transporting glass gently, carefully and safely is tricky. Grenzebach says its specially developed drive train with direct drive represents a major step forward.

The number of components in the drive has been minimized and access to key components is now even easier. This enables companies to significantly reduce the cost of spare parts and maintenance.

And with the new collaboration app, Grenzebach says the work on the conveyor system is now even easier.

The operators of float glass plants want continuous production 24 hours a day, 365 days a year. Conveying technology is the connecting element in a float glass plant.

Grenzebach has always been committed to transporting glass gently and safely. The new generation of conveyor technology now provides even more dynamics, reliability and also saves resources – a big step into the future.

Markus Schmid, senior manager mechanical concept engineering at Grenzebach, says: “Every hour of standstill costs the operators of glass plants immense money.

“With our new generation, we are once again increasing the availability of conveyor technology, and significantly fewer resources are required for spare parts and maintenance.”

Direct drive brings many advantages

The newly developed drive train with direct drive works without the usual belts and drive shafts. This provides even greater dynamics during transport, increases efficiency and also reduces the requirements for spare parts storage and maintenance.

Schmid says: “These service-intensive components have been eliminated and are now a thing of the past for conveyor technology.”

The new drive train also makes it possible to use all common motors. Newly developed bevel gears are used to transmit power to each roller, which not only guarantee smoother running – but above all, much more precise positioning.

With this innovation Grenzebach underlines the demand for gentle and precise glass transport along the entire production line.

Free view of key components at all times

Another novelty is that, due to the compact design, all components are arranged below the conveying level. Access to the drive train is provided by a continuous transparent protective cover.

This means a clear view of key components such as gears and shafts at all times. The innovative lock system allows quick and easy access for maintenance work. Thanks to a special plastic mixture, the protective cover is almost unbreakable, durable and perfectly suited to the harsh requirements.

Change over now and save resources permanently

Florian Nagler, head of customer service at Grenzebach, says: “The advantages of the new generation of conveyor technology naturally are also open to the operators of existing glass lines. As a competent service partner, we retrofit lines so that they can benefit too.”

Provided that the necessary preparations have been made, the conversion of a drive to the new conveyor technology generation can usually be completed in less than three hours.

That’s well invested time, which results in lasting and substantial savings in resources. Downtimes due to maintenance work are eliminated and the production yield is increased. The maintenance intervals and scope as well as spare parts requirements are reduced.

Impulses and wishes of customers taken up

Impulses and requests from the operators were decisive for the development of the new conveyor technology generation.

Schmid says: “As a sparring partner of the industry, an ongoing exchange of ideas to optimize the technologies is just as important to us as optimal support in day-to-day business.”

Less downtime, predictable maintenance and thus lower costs: with this focus, Grenzebach supports the further development of systems throughout their entire life cycle.