Merkle relies on Kassow Robots for complete robot welding systems

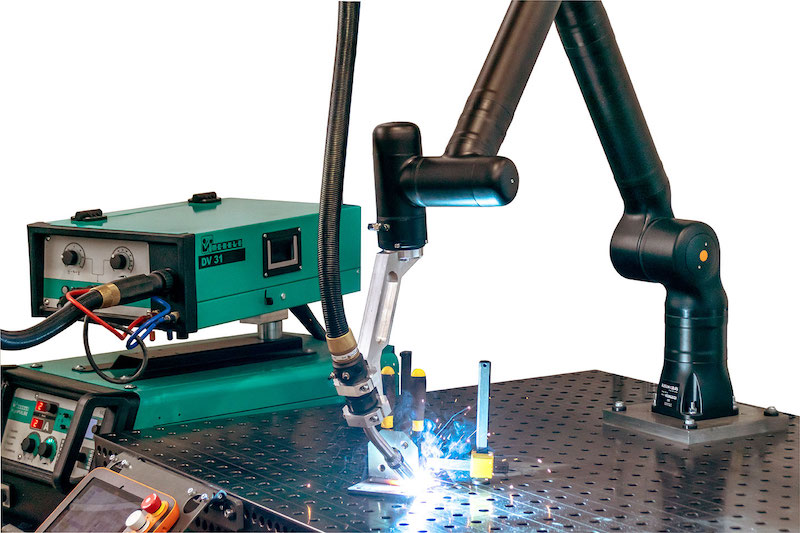

Merkle Schweissanlagen-Technik, or Merkle Welding Systems, will use 7-axis cobots from the Copenhagen-based collaborative robot company Kassow Robots as standard in its WeldROB complete robot welding systems from now on.

Dr Ulrich Prank, deputy managing director of the medium-sized company located in Koetz in Bavaria, Germany, says: “We have always focused on innovation. The lightweight robots from Kassow Robots are a new generation of particularly powerful and flexible cobots and offer our industrial customers real advantages.

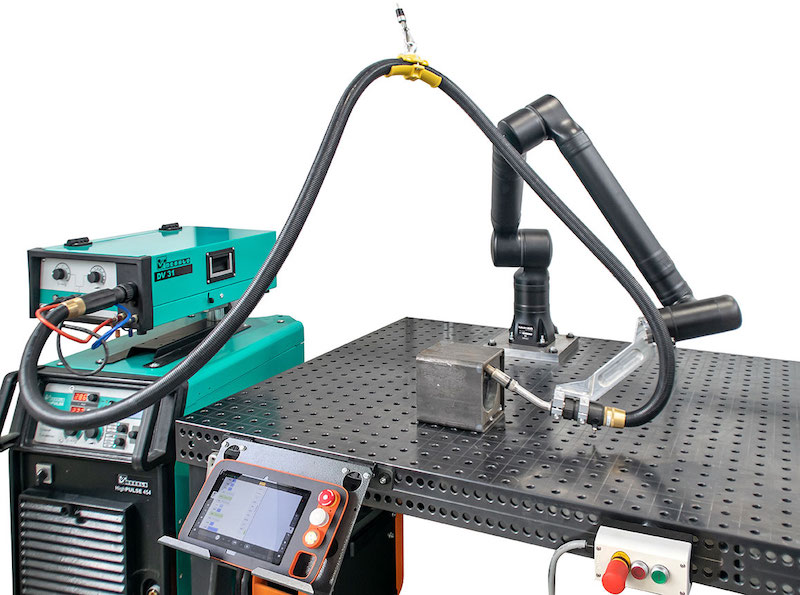

“Instead of complex, elaborate robot technology with a high need for training and familiarization, welding with the WeldROB 7 is surprisingly simple.”

7th axis enables ‘particularly simple and exact welding applications’

Kassow Robots’ collaborative robots’ 7 individually controllable axes allow “the highest flexibility”, says the company. The movements of the cobots from Kassow Robots are very close to the movements of human arms, especially since the 7th axis allows the robot arms to also reach around corners.

This makes it possible, among other things, to exactly follow predefined paths while maintaining the specified speed and without setting down.

Dr Ulrich Prank, says: “All cobots from Kassow Robots also have three ports with various I/Os and power supply signals as well as an Ethernet interface installed as standard on the toolhead. In addition, the free drive button allows completely new freedom when programming waypoints.

“Welding with Kassow Robots’ cobots is easy. The welding robots can be set up and integrated into the work process within a few hours, without special electrical installation, instead with simple plug & play accessories.”

The use of the WeldROB 7 system is not limited to short longitudinal welds. With the new WeldROB 7, simple welding processes such as circular and longitudinal welds, but also complex contours and segments can be programmed and automatically welded in just a few minutes.

Automation with cobots ‘counteracts shortage of skilled workers’

Dieter Pletscher, sales manager at Kassow Robots, says: “Merkle stands for both sophisticated and compact complete systems for highly efficient, automated welding. This is a good match, because with our 7-axis cobots, we supply the company with the latest cobot technology.”

In times of staff shortages, particularly in the field of welding technology, Pletscher sees a great opportunity for companies to develop skilled workers and automate monotonous activities.

Dieter Pletscher is looking forward to the Koetz-Copenhagen cooperation and even regards the automation in the field of welding as a perfect example for other applications, where the lack of skilled workers slows down the growth of medium-sized companies.

“Our cobots simply and effectively relieve skilled workers who can devote their time to other specialized tasks in the meantime.”