Okuma makes ‘conversational programming’ standard on its CNC machines

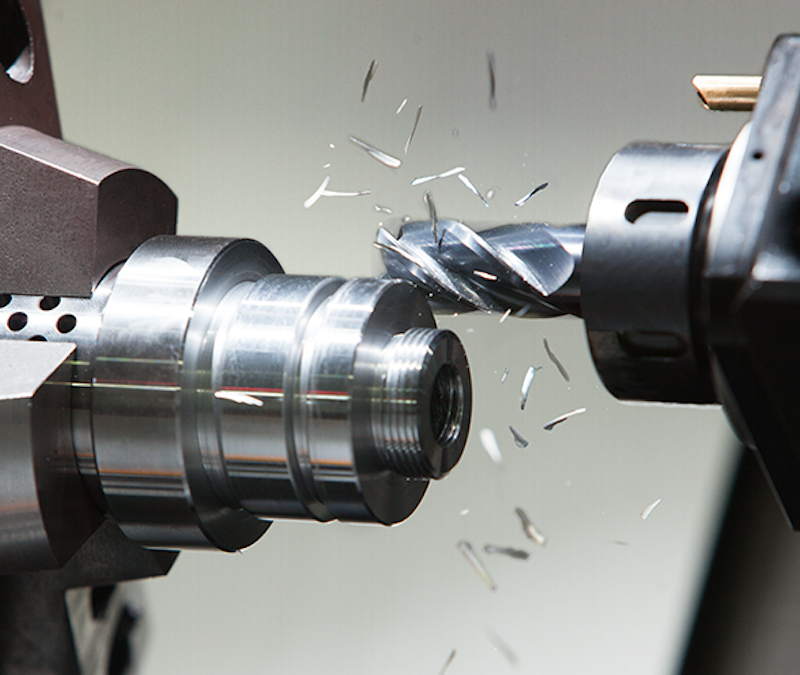

Okuma, one of the world’s largest manufacturers of industrial equipment, has introduced “conversational programming” as standard on its CNC machines.

Okuma says its Advanced One Touch (AOT) conversational programming software enables shops to “easily create programs without the need for highly-trained programmers, achieve faster setup times, and increase machine productivity”.

Okuma America says that select machines from Okuma’s core product line now come equipped with the Advanced One Touch-Interactive Graphics Function (AOT-IGF), the conversational programming software designed for Okuma’s lathes, machining centers and multitasking machines.

AOT enables shops to easily create simple part designs without the need for highly-trained programmers, achieve faster setup times, and increase machine productivity.

With AOT onboard, a highly-intuitive graphical user interface provides step-by-step instructions that guide operators through the process of selecting material type, tooling, processes, and cutting motions for the desired part design.

From there, the system then simulates the cutting process in a 3D graphical view before exporting the NC (numeric control) program.

Using AOT to create custom programs allows shops to maximize their machine tool’s full potential, while eliminating concern regarding correct program syntax.

Shops that do not currently have AOT installed on their machines can give Advanced One Touch a try by downloading a free 60-day trial.

The trial version is for use on a PC and will provide an interactive preview of the functionalities and benefits of the software. For more information and to download the free trial visit Okuma’s AOT webpage.