Yaskawa achieves 30 million total shipments of AC drives

Yaskawa, one of the world’s largest manufacturers of industrial robotics and automation technologies, says it has reached 30 million total shipments of alternating current drives.

An AC drive is a device that is used to control the speed of an electric motor, which are present in almost all robots and automated machines.

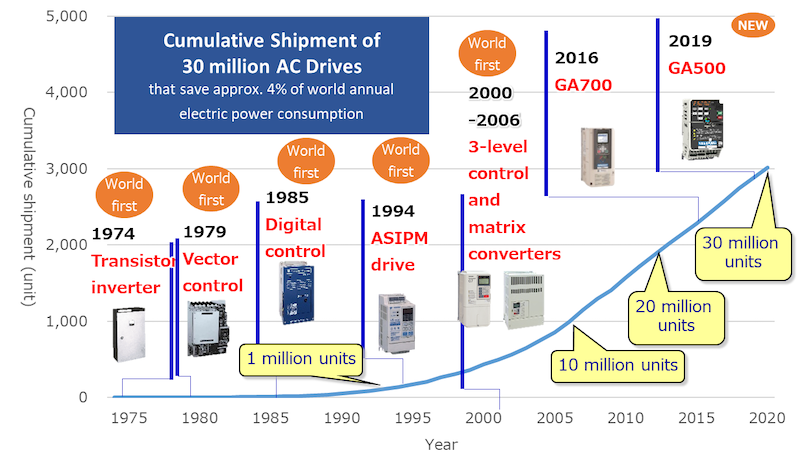

In a statement, Yaskawa, which shipped the world’s first transistor inverter in 1974, says: “We are pleased to announce that the cumulative shipments of AC Drives reached 30 million units in January 2021.”

The Japanese company – which first coined the phrase “mechatronics” – has developed a number of products incorporating innovative drive technologies, such as vector control, digital control, IGBT (Insulated Gate Bipolar Transistor) drive, and ASIPM (Application Specific Intelligent Power Module) drive.

The results of these developments have led to widespread adoption as the de facto standard (global standard) in the industry, supporting social infrastructure such as elevators and air conditioners along with global economic growth, and contributing significantly to improving production efficiency, quality, as well as saving energy and reducing CO2 emissions.

In addition, drive technology, such as 3-level control and matrix converters, which Yaskawa claims it is the only company to have commercialized as general-purpose AC drives, has been highly evaluated for solving customer’s problems.

In April 2016, Yaskawa began sales of the GA 700, CR 700 and GA 500 in which “state-of-the-art” motor control functions were implemented as components and added software value such as alerts for abnormal conditions that do not stop the machinery and equipment.

At production sites, Yaskawa says smart factories are being promoted to improve production efficiency and quality and ensure traceability.

To this end, Yaskawa is promoting a solution concept that incorporates digital data management in addition to automation, called i3-Mechatronics.

Yaskawa says its AC drives “not only improve performance by increasing speed and response, but also monitor machine operation at high speed through motor control”, and from this data, the company aims to provide digital data solutions that “realize high production efficiency, high quality and continuous production”.

In 2019, Yaskawa merged the AC drive business with the PM motor business, which is highly compatible with AC drives. By combining the motor technology and control technology, the company says it aims to strengthen its “industry-leading solutions” for miniaturization and energy conservation.

Furthermore, Yaskawa will respond to the diverse needs of the market by establishing five global production bases – Japan, the United States, China, Europe and India – and four global development bases – Japan, the US, China, and Europe – as well as by establishing sales bases in each region and strengthening its service system.