ABB unveils new ‘compact’ robotic interior painting system

ABB has unveiled a new “compact” robotic interior painting system, mainly aimed at the automotive manufacturing sector.

The Compact Interior Painting station enables automotive manufacturers to reduce the size of their vehicle interior painting stations by one-third, while saving costs and making automotive paint facilities more sustainable.

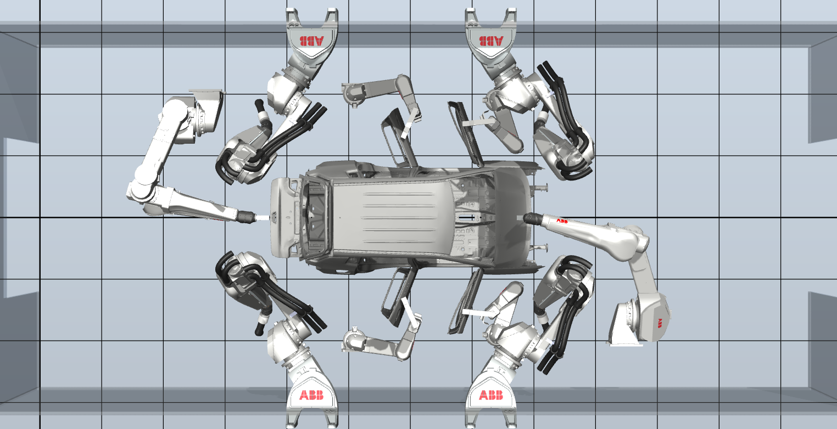

ABB says its latest innovative solution for automotive manufacturing – the Compact Interior Paint station – combines 12 robots to offer a space-saving alternative to traditional robotic interior painting solutions, helping automotive original equipment manufacturers reduce the footprint of their paint booths “by up to 33 percent”, while being able to paint a variety of vehicle types, from cars and SUVs to large MPVs.

With four IRB 5350 door opener robots for opening the doors and two IRB 5500-22 robots to open hood and trunk, the key to the compactness of the solution is the capability brought by six of ABB’s new IRB 5500-27 7-axis robots.

Featuring a class-leading 3.8 meter working envelope and offering a choice of floor, wall or inverted mounting options, the extended reach offered by the IRB 5500-27 allows the robot to reach further across a car body than other robot solutions.

The enhanced working angle reduces the number of robots needed to carry out a particular task and eliminates the need for a linear track.

The improved reach also enables the robot to optimize the angle of the atomizer relative to the surface to be painted, which helps to reduce paint wastage by minimizing overspray, while the space savings achieved by ABB’s Compact Interior Painting Station reduces the need for ventilation and illumination on the factory floor, helping to make paint operations more sustainable and cost-effective.

Another benefit is the ability of the robot to be able to compensate for the one next to it to maintain productivity. In the event of a failure, the remaining working robot will enter degrade mode, either increasing speed to cover the work of both robots or increasing cycle time to cover for the failed robot until it can be brought back online.

The use of ABB’s SafeMove software ensures that the robots can work in close proximity to each other. By setting each robot’s working envelope as a safety zone and using it to control their speed and movement, the risk of a collision or triggering of an emergency stop is removed.

The use of SafeMove also helps to prevent injury to workers who may have to enter the booth, with the robots brought to an automatic stop as soon as a person is detected.

Jörg Reger, managing director Automotive OEM for ABB Robotics, says: “Our Compact Interior Painting Station is the latest development in our mission to help automotive OEMs find new ways to enhance their flexibility and reduce production costs and their impact on the environment wherever possible.

“By removing the need for ancillary equipment such as the linear track and additional ventilators, the Compact Interior Painting Station can help to significantly reduce the time and cost of setting up a paint booth.

“With its ability to fit into different booth configurations, and with fewer items that need to be installed and maintained, it presents an ideal solution for retrofitting existing paint shops.”