AI Enabled Robots are Coming

By Michael Frankland, Business Consultant – Factory Automation, Pivot Search

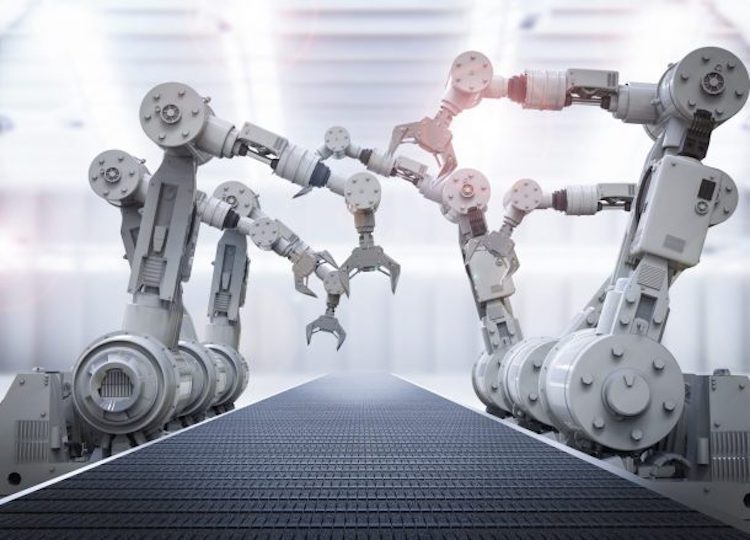

We’ve entered a new age of automation: the artificially intelligent robots are coming.

When AI enabled robots hit the manufacturing mainstream, the implications will be huge.

With the right combination of hardware, robotics will have an application in manufacturing for nearly every industry. Processes will become quicker, more accurate and more cost-effective.

Robotics in Manufacturing

The first thing to note is that when we talk about robotics within this article, we are referring to a physical piece of hardware without the ability ‘to think’ for itself, usually due to a lack of appropriate software and/or hardware.

Right now, most industrial robots are not artificially intelligent and are only programmed to carry out a repetitive series of movements, usually within a caged environment separated from humans. This has limited them to high structure, low variable industries like automotive and electronics. So, industries with non-standard products like food, pharmaceuticals and clothing; have yet to enjoy the benefits of robotics and automation.

This lack of flexibility is mainly down to the fact that non-AI robots aren’t intuitive, which has been the main barrier that’s stopped the technology from hitting the mainstream – even the industries with the highest degree of automation, are a long way from having ‘lights out factories’ with full automation.

However, times are changing.

AI software has led to machines that can think and act for themselves. This is a real game changer in the automation industry and has the potential to revolutionise the manufacturing industry.

It will give robotics the ability to work with different types of objects in a variety of industries, collaborate safely with humans and continuously learn from their mistakes to make processes more efficient. So, who are the companies offering pioneering AI software for robots?

Taiwanese start-up Solomon 3D is at the forefront of the AI enabled vision solution space Its innovative solutions led the company to being awarded the CIIF Robotics Award and the Vision Systems Design Innovation Award in 2019.

Solomon 3D’s AI software is used throughout its product line, with its best application in its AccuPick 3D. This revolutionary solution uses AI software which recognises and plans moves without any human programming.

This enables the robot to carry out a variety of challenging bin picking tasks with objects of varying size, weight and consistency without human interaction. The fact that it doesn’t require programming saves huge amounts of time and ultimately money particularly in bin picking applications.

Solomon 3D are not alone in the world of AI enabled vision solutions for bin picking applications, with competitors like Photoneo and OMRON offering similar solutions.

Omron are a one-stop shop, which can provide the robot, vision system, end of arm tooling, and software. Its vision systems use AI to self-program the robots live, so they can adapt to objects that differ in size, shape and weight.

If you get the chance, have a look at how they showcase this technology. I found watching robots playing table tennis is very entertaining.

That’s not all Omron are contributing to this space. At the start of 2020, they also debuted a self-diagnosing robot, Omron i4, that can tell when it needs repairs or routine maintenance. This improves efficiency in manufacturing by staving off disruptions caused by failing equipment.

AI Supports Human-Robot Collaboration.

As mentioned earlier on, industrial robots are usually encased in large cages to preventing any injuries on the manufacturing floor.

This is not an optimal environment to make the most out of either the robot or the human worker and limits manufacturing flexibility. Collaborative robots have been marketed as the solution to this, however, they have their limitations from a payload, speed, and safety perspective.

Veo Robotics has created intelligent software that incorporates advanced computer vision and 3D sensing that removes the need for large cages around industrial robots. They are lighting up the world of manufacturing, partnering with some of the biggest robotic companies in the world including Fanuc, Yaskawa, ABB, and Kuka.

The company’s software, Veo FreeMove, improves our current, standard, industrial robots by teaching them how to act safely around humans, therefore freeing up space by removing the large cages and allowing industry to benefit from the dexterity and intelligence of humans, combined with the strength and speed of automated robots.

The Future of AI Robots

AI is breaking down the barriers that have restricted robotics throughout the technology’s existence.

When combined with the right hardware, AI enabled robots will enable automation in virtually all parts of manufacturing, and due to the nature of AI and machine learning, this technology is only going to get better. The more data gathered, the quicker the software will learn, leading to ever increasing efficiencies in manufacturing facilities.

I can’t wait to see how this technology evolves, with its potential beyond measure.

About the author: Michael Frankland is a global recruiter in the factory automation market at Pivot Search. If you’d like to discuss this article with him further or are interested in his recruitment services, you can find him here on LinkedIn https://www.linkedin.com/in/michael-frankland-7350146b/”