How to Choose a PCB Assembly Company?

Once you have printed your circuit boards after putting in a lot of hard work and time, the next phase is assembling them.

When it comes to PCB assembly, you have to be very careful with it. If you get even a tiny bit careless with it, you would not be able to do justice to your entire project.

A lot of companies outsource their PCB assembly to PCB manufacturers or assembly companies.

There are many PCB assembly companies out there and if you are planning to hire one for your project, you need to make this decision wisely. Below I have mentioned a few important things that will help you choose the right PCB assembly company. Let’s have a look:

How Does The PCB Assembly work?

If you want to choose the right PCB assembly company, you will have to first understand the process of PCB assembly and what goes into it.

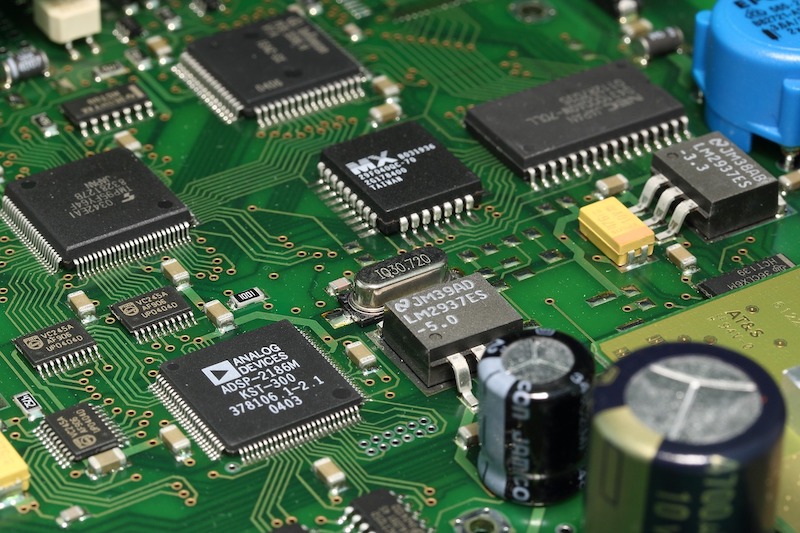

PCB assembly is a process in which a printed circuit board is filled with electronic components so that it can become functional. It is the addition of these electronic components that complete the circuit and makes the board usable.

There are two ways in which most companies do PCB assembly. This includes Surface-Mount technology and Through-hole manufacturing.

Surface-Mount technology:

This is the method that is used for assembling the majority of the printed circuit boards. The products that can be created with this method are 1/10th the weight and 1/3rd the size of boards that are created via through-hole manufacturing.

It is a faster and cheaper way of board assembling, and in this method, the electrical components are attached directly on the board.

Through-hole manufacturing

This one is an older way of PCB assembly and is quite a durable one. In this method, holes are drilled in the board, and the units are placed in those holes. The pads are soldered with the leads on the opposite side, which makes for a strong assembly.

This method of assembly is expensive compared to Surface-Mount technology and takes a lot more time as well.

However, if your boards will end in an environment where they will have to stand a tough environment or high current, then it is safer to go with this manufacturing method.

You can also use a combination of both methods, depending on what kind of product you are making.

Follow a Proper Timeline

If you are not giving much thought to the PCB Company you are choosing just because you can move your project further quickly and maximize your profits by finishing the product earlier, it might backfire.

In the long run, rushing through this decision can cost you greatly. So, be patient when choosing a PCB assembly company and follow the right procedure for hiring.

Do your research and understand the company you are planning to choose more deeply. Take a look at the quality of their work and also find out whether they are punctual or not.

A good PCB assembly company never makes any delays and follows a timeline. If you feel like the company is a bit sloppy with their dealings, then you should consider another option instead of bringing them onboard. You do not want the project to be delayed, as it can cause a lot of harm to your business.

So make sure that you go with a PCB assembly company that will stay true to its word and will deliver right on time. You can also consider Mktpcb Company as they are quite punctual with their deliveries.

Experience Matters

It does not matter what kind of service you are hiring for your business; experience matters a lot. It is vital for you to hire a PCB manufacturer who has enough experience to match your project’s requirements.

If you come across their brochures or website, then you must look for answers for the following:

What kind of manufacturing they have experience with, through-hole manufacturing, surface-mount technology, or both of them?

What projects did they work on, what kind of products did they make, and what electrical components they used in their manufacturing in the past?

On what scale do they typically work, and what’s the biggest project they have handled in the past?

What kind of industries have they collaborated with?

DO they offer any other services or not?

In short, you need to hire a company that has enough experience to finish your project to the last minute detail. That way, you will know that there is nothing that will cause confusion for the PCB assembly company.

You should also ask more simple questions like how long they have been in business and how many clients they have served over the years.

A company that has been in business for years will have experienced professionals and team members will be able to handle your project better.

Evaluate Quality

Another thing you need to keep in mind while hiring a PCB assembly company is its quality. You do not just want the company to do the work on time, but you also want them to provide quality.

However, judging the quality of anyone’s work is not easy until you have seen it yourself. But there are ways in which you can get an estimate of their actual quality.

The best way to do that is to place a small order that will be finished within a few days, and you can judge it’s quality hands-on. Apart from that, you can look into the following to gauge the quality: certifications, equipment, and client feedback.

If they use the latest machinery with the best ratings, it indicates you will get quality work. Similarly, certifications are not earned easily, and the company has to go through a rigorous process to earn them.

Lastly, you can check the client’s feedback by checking the reviews on their site and social media.

Excellent Testing Services

A good PCB assembling company offers decent testing services as well. When you are doing a project on such a scale, quality testing becomes vital.

If you don’t put your products through quality tests, then you can end up with major losses. And it would not just hurt you financially but can damage your company’s reputation as well.

So before you choose a partner, you should ask them about their testing procedures and quality control. Go for companies that have more than one testing procedure that will never compromise on the quality.

Customer Support

It is vital for you to make sure that the company you are hiring is providing good customer support as well. You do not just want to work with a business that has the best equipment and are fast, but you also want to ensure that they can provide you with solutions when needed.

So, do not settle for a company that does not have a good customer support service. The quality of customer support can be judged quite easily as all you have to do is engage in a conversation with the company’s representative.

If he behaves nicely towards you and encourages you to ask questions, then that means they care about providing the best customer support service. On the other hand, if the representative seems disinterested, then it is not a good sign.

Compare Costs

Lastly, you must ask all of the shortlisted companies to give you a quote for your project and compare it accordingly.

When it comes to comparing cost, you do not just want to see which one is the cheapest. You want to go with the option that is providing you with the best value for your money.

For example, company A might be much cheaper than company B, but their quality is not as good as them. In such a case, you should prioritize quality and go with the better option.