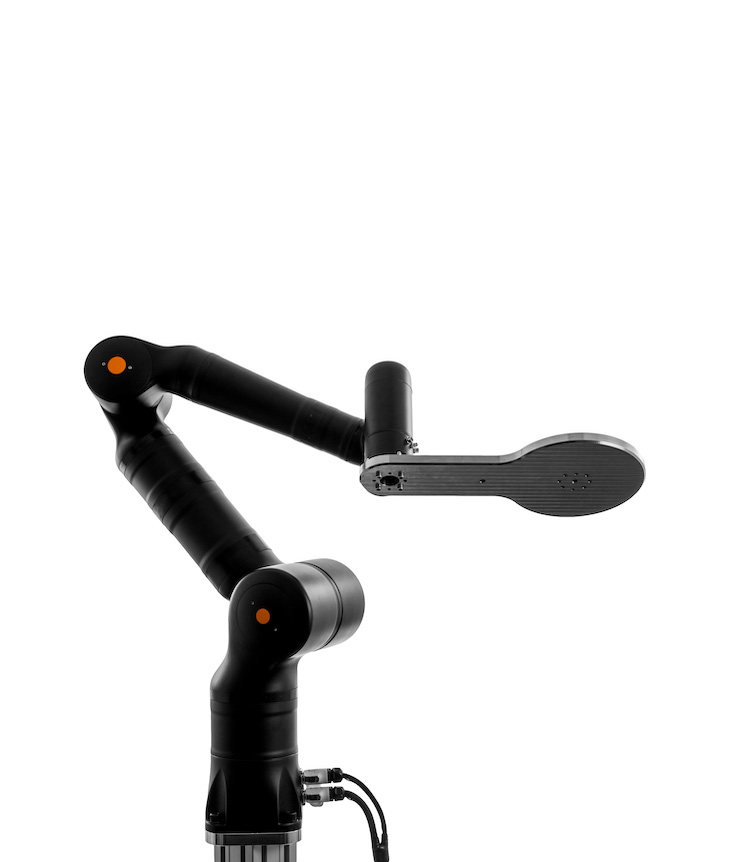

Kassow Robots launches the 7-axis lightweight cobot KR1018

The Danish company Kassow Robots has expanded its product portfolio with the addition of the KR1018, a new, particularly strong model that can handle payloads of up to 18 kilogrammes.

The cobot itself weighs just 34 kilogrammes, a feature that enables it to meet a fundamental requirement for flexible automation solutions, especially in narrow spaces.

The special target group for the company’s fifth 7-axis cobot is industrial companies in the metalworking industry and other areas like the food-production sector that want to take the heavy lifting off the hands of their employees and have these individuals take over more demanding tasks.

First introduced to the market in 2018, Kassow Robots’ product family now comprises five 7-axis cobots that handle payloads of up to 18 kilogrammes and offer a reach of up to 1.8 metres.

All that with a speed of up to 225 degrees per second and weighing only up to 38 kilogrammes: KR810 (850 mm reach/ 10 kg payload), the new KR1018 (1000mm / 18 kg), KR1205 (1200 mm / 5 kg) KR1410 (1400 mm / 10 kg), KR1805 (1800 mm / 5 kg).

Each of the five cobots can be used in virtually endless industrial applications involving human-robot collaboration – thanks in part to the 7th axis that can reach around a corner.

“Compact, very strong – but lightweight! This was the goal that Kristian Kassow had in mind when he designed his cobots for flexible jobs at industrial companies, and he brought this design to life with the help of his team,” says Dieter Pletscher, the Head of Sales at Kassow Robots.

“Kristian sketched out the five models in the business plan and all are now being sold in the market. All five models offer a unique combination of strength and speed. They are also easy to operate and programme.”

The KR1018, a cobot that can handle payloads of up to 18 kilogrammes and comes with 7 axes, can perform such tasks as the loading and unloading of heavy parts for the metalworking industry or tasks as heavy lifting in the food-production sector.

Such a change will make the lives of employees easier. Once in operation, the KR1018 provides employees with more opportunities and flexibility, allowing them to be assigned to jobs that require less physical effort.

Small and medium-sized enterprises will profit tremendously by introducing or

expanding lightweight robot solutions in their operations.

“Everybody has gotten to know the intuitive and user-friendly technology of tablet computers in their private lives,” Pletscher says.

“This is why small and medium-sized enterprises that have had nothing to do with robotics in the past will be able to easily enter the world of programming our cobots.”

Pletscher also stressed one other point: In his selection of integrator partners, he makes sure that they speak the same language as potential customers do.

“Our integrator partners are also small and medium-sized enterprises, and they can put themselves into the shoes of end customers when it comes to industry automation. The integrators are the main contact who can answer customer questions and help to integrate our cobots into existing automation solutions.”