Trapo unveils automated truck loading and unloading system

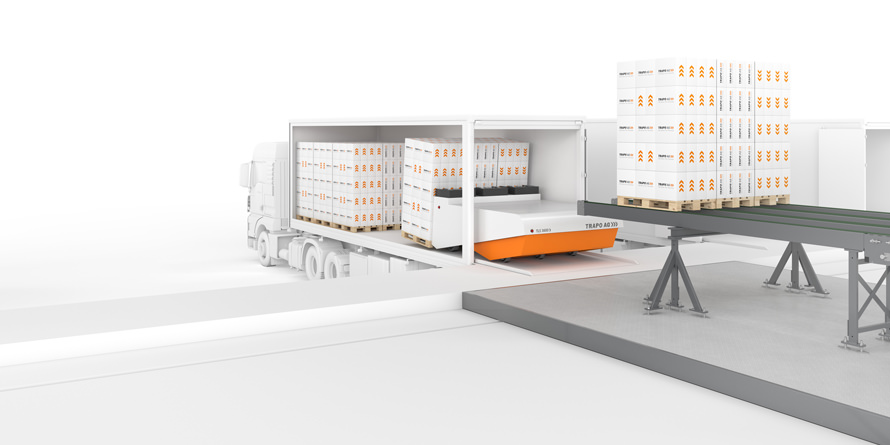

Trapo has unveiled an automated truck loading and unloading system – the Trapo TLS 3600.

The Trapo loading system (TLS) is a fully automated logistics solution for the efficient, inexpensive and safe loading and unloading of trucks and containers with pallets.

With the cross-sector solution, Trapo closes the gap between the warehouse and loading ramp and once again proves its overall system competence.

The Trapo loading system has already been registered for a patent in terms of function and design : the space-saving car loader is only 4.30 meters long, only 1.30 meters high and can hold up to 3.6 tons of payload per row.

Comparative products are much longer and less mobile. Optionally, the TLS can be placed on rails and thus moves across the loading axis in order to operate several hubs.

It can be integrated into any production, storage and sequencing system.

Depending on the requirements, several TLS operate in a loading zone at the same time. So that the car loader can also be used in high care areas such as the food industry, pharmaceutical industry and medical technology, Trapo also offers all components in stainless steel.

Process of pallet processing

Trucks and containers are loaded with pallets in four sequences. First, pallets are placed next to each other in rows on the stationary part of the TLS. The mobile loading unit then picks up the rows and then transports them to a truck or container.

At the loading ramp, the TLS not only compensates for height differences independently – it navigates autonomously, avoids obstacles that occur and also compensates for differences on the ramp.

The discharge then proceeds in exactly the reverse order. For example, the car loader reduces the loading time of a 13-meter trailer with a capacity of 33 pallets to around 15 minutes.

“As a partner for industrial automation, we develop overall line concepts to anticipate the needs in intralogistics. The TLS closes a security gap and increases efficiency,” explains Dr. Stefan Kurtenbach, Technical Manager Construction / R&D Trapo.

Complete line solutions for the packaging industry

Trapo has also developed a “fully automated, smooth pallet handling” system for when the driverless transport system of the TTS series takes over live pallet transport between the warehouse and the Trapo loading system.

The Trapo Intelligent Management system is designed to provide security, controls, monitoring and provides system statuses and evaluations around the clock.