Omron launches simulation software for automated factories

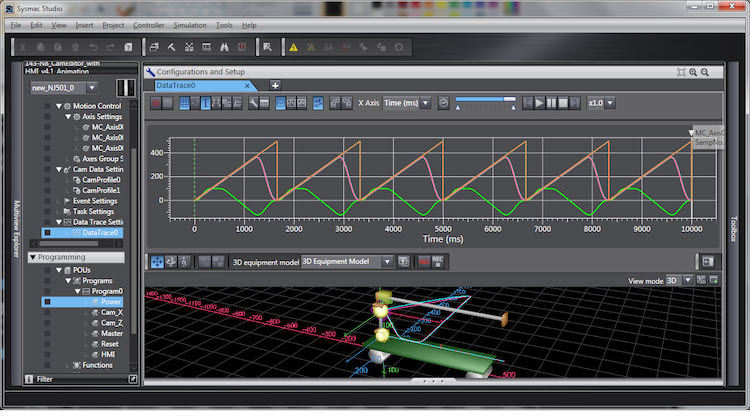

Omron is making available its Sysmac Studio 3D simulation software available to industrial companies. (See video below.)

The company says it will be the first in the industry to provide such a system, which “can integrate and verify the movements of robots and peripheral devices that make up facilities”.

Omron says its “extensive knowledge and technology of control equipment”, including robots, helped in its development of the software.

Sysmac Studio 3D is said to be able to reproduce the entire facility digitally and verify the operation “with the same accuracy as that of an actual machine”.

Omron says it will use Sysmac Studio 3D to innovate its customers’ work efficiencies and their facilities’ production capacity.

In recent years, in order to respond flexibly to the diversification of products and fluctuations in demand at manufacturing sites, manufacturing must be sophisticated, including rapid changes in production sites, shorter delivery times for equipment development by simultaneous start-up of production lines at multiple sites, and high-precision assembly.

Meanwhile, there is a shortage of skilled engineers to realize these, and efforts are being made to facilitate facility design through advance verification using simulations.

However, since conventional simulators are dedicated software, they are expensive and require expertise.

Furthermore, since a software differing from the controller controlling the facility is used for the simulation, it is difficult to match the simulation results with the actual machine operation.

In addition, it has been difficult for robots which are increasingly being introduced as a solution to worker shortages to make high-precision simulations linked with peripheral equipment since dedicated controllers are needed for them.

“Sysmac Studio 3D Simulation” simplifies operational simulations of manufacturing facilities by simply adding optional licenses for simulation functions to the programming software “Sysmac Studio” of OMRON’s flagship automation controller for machines “NJ/NX Series”.

Omron says that, by becoming the first in the industry to be able to control and verify robots and other peripheral equipment in a single operation, it will innovate the efficiency of facility design and the improvement of facility production capacity.

Operational simulation can be performed with high accuracy and real-time since it is based on the emulator method.

In addition, this system makes equipment digitally visible and enables preliminary verification of movements before it is actually started up, so the time required to confirm the production capacity of the equipment, start-up, and modification is shortened.

Furthermore, the operating status of the actual equipment is checked and monitored digitally after facility operation, thereby this system contributes to a shorter time to clarify the cause of abnormalities.

Omron is working to innovate a variety of manufacturing sites under the strategic concept “innovative-Automation”, consisting of three innovations or “i’s”:

- “integrated (control evolution)”;

- “intelligent (development of intelligence by ICT)”; and

- “interactive (new harmonization between people and machines)”.

In the future, by enabling robots and peripheral devices to be controlled and simulated with a single controller, Omron says it will accelerate the “integrated (control evolution)” and “intelligent (development of intelligence by ICT)” at the manufacturing site, which will be the key to realizing “innovative-Automation” and will “dramatically improve productivity at the manufacturing site”.

The main features and advantages of integrating the Sysmac Studio 3D Simulation Function include:

- Enables the mechanical designer responsible for setting equipment specifications and the electrical designer responsible for facility control programming to discuss and design concurrently at an early stage of facility design. As a result, facilities can realize high production capacity and prevent errors and turn-back at the time of equipment startup, realizing short-term startup.

- Real-time connections with actual equipment are not required because emulations in Sysmac Studio are used to run simulations. In addition, the facility’s production capacity can be grasped digitally.

- Realizes easy startup of the next facility through the reuse of digital past assets.