Yaskawa launches ‘explosion proof’ industrial robot for painting

Yaskawa Electric has launched what it describes as an “explosion-proof” industrial “handling” robot.

The new Motoman MHP 45L has a payload capacity of 45 kg, and maximum reach of 2,850 mm for painting areas using volatile paints.

Yaskawa says it has lined up a “wide range of painting robots” optimized for various applications from small to large applications such as smartphones or automotive.

Up to now, workpieces in a painting area has been usually transferred by using a dedicated machine for transfer or a painting robot with an explosion-proof function, because there were processes such as spraying volatile paint in the area.

However, these painting robots were not optimized for transfer, there were limitations on the types of workpieces to be transferred due to the upper limit of the payload and elsewhere.

In response to these restrictions, Yaskawa has now launched the Motoman MHP 45L handling robot, which equips explosion-proof function and can transfer large workpieces weighing maximum 45 kg.

This robot can be installed in the painting area, making it possible to design the area compact and to save space of painting lines that do not require dedicated equipment for transfer.

Yaskawa says the key features of the new robot include:

1) Improvement of working environment in painting area by handling robot with high payload capacity and flexible operating range

A handling robot with a payload capacity of 45 kg can transfer large workpieces. With a maximum reach of 2,850 mm, the range of operation is flexible.

And while avoiding interference with painting robots and other equipment in the painting booth, the effective range of operation around the robot can be expanded, improving the work environment in the painting area.

The booth can be designed to reduce the size of the painting booth, contributing to the reduction of CO₂ emissions and running costs thanks to the air-conditioning in the booth.

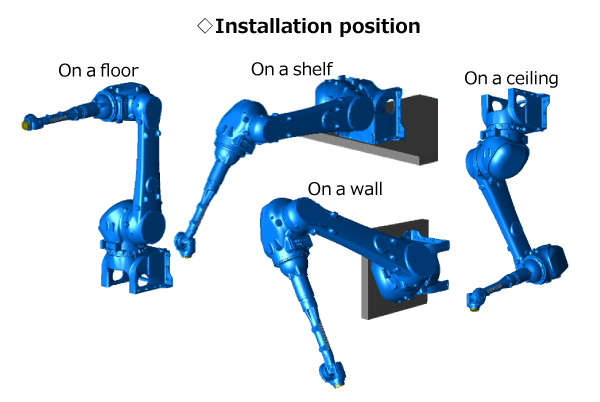

2) Correspondence to a variety of installation positions

The robot can be installed on the floor, on the wall, on the ceiling, or on a shelf, and can be flexibly laid out to suit customers’ demand for production.

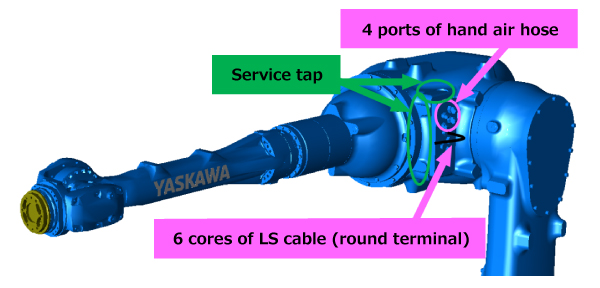

3) Deployment of handling equipment

It deploys 4 ports (φ10×2, φ6×2) of hand air hose and 6 cores of LS cable on the casing side of the upper arm.

Additionally, a service tap is provided in the surrounding area, enabling a cable-less installation. Minimizing the interference space by installation cables contributes to maximizing the effective operating space.

Yaskawa adds that the robot’s main applications include transfer of workpieces and loading of paints and solvents in the painting area.