Drift Eliminators Used In Cooling Towers

To understand how cooling tower drift eliminators work, it is of great importance to first understand what cooling towers fundamentally are.

Basically cooling towers as the name suggests are an integral part of large scale industrial cooling systems.

Basically, it is used as a heat removal device, which works on the basic principle of evaporation. Their main purpose compromises of reducing the water temperature used in industrial cooling operations.

Drift Eliminators are an important component of cooling towers for many reasons. One of its many uses includes; its role in the escape of vapors and mist from the tower.

Similarly, they help in getting rid of unwanted or excess heat in a cooling system. How it does so is by capturing large water droplets that get caught in the cooling tower’s airstream.

Perks of Drift Eliminators

These drift eliminators not only make the life span of a cooling tower longer, but also more efficient as well.

The benefits are as follow:

- These eliminators help effectively recycle water. They help in allowing leakage of chemically polluted water out of the cooling tower.

- This helps in significantly reducing the release of harmful chemicals and toxins into the environment that can prove dangerous or even lethal.

- They are high performance as well as cost-efficient.

- They help in adding both years and reliability to the life of the cooling towers by inhibiting corrosion of its system and parts.

- Using drift eliminators are a great way of conserving energy use.

- These also prevent the icing of nearby fields and roads.

- These mainly aid in the reduction of water loss and emissions.

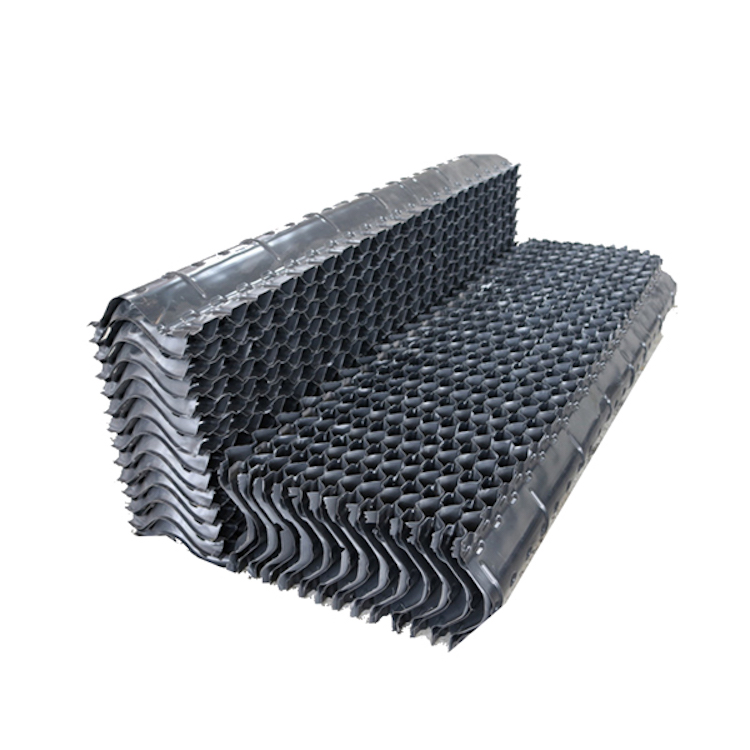

How Drift Eliminators Are Constructed

People often confuse drift eliminators with complex machinery but these are simple yet important devices that perform a deal of work.

Despite including just a few simple components. All the simple components combine to help greatly increase the efficiency of the cooling system.

Listed below are some of the major components used to construct drift eliminators:

Seal

The main purpose of a seal is to inhibit drift bypass. Seals are generally instilled during the fitting process. As a result, water droplets are restrained from escaping out of the system, in the rerouting course.

Sifter

The filter helps to remove impurities such as elements and toxins that can be on the loose into the atmosphere and prove potentially harmful or even lethal.

Walls / Blades

They are available in diverse designs. The function of which are all the same. They are used to direct the flow of water. It moves the stream into the preferred route. Liable up on the type of design it has, vapors are forced again in the tower by this essential part of the eliminator.

Available categories of drift eliminators in cooling towers

The drift eliminators come in many different working-models which are all combined and categorized into two main groups for easier recognition. The two main groups are as follows:

Counterflow Drift Eliminators

This category of drift eliminators uses a contrivance where the air passes in an upright trail through the fillings at the topmost.

Contrarily, exhaustion of more air is made possible by the water flowing from the top to the bottom. This process of exhausting air is quicker than the procedure of drawing the air in.

Gains:

- Consumes a reduced amount of energy.

- Repairs are nominal.

- Lower pump head.

- Plume Abated Systems.

Crossflow Drift Eliminators

Crossflow drift eliminator has a horizontal airflow while water flows in the same downward manner. This category of eliminator furthermore uses a splash form of fill.

Advantages:

- Minimal noise.

- Cost-effective.

- Low maintenance required.

- High performance.

- Consumed energy is optimized.

Parts of Drift Eliminators and their Function

In the market, different designs of drift eliminators are available. All differentiated by the way they are installed, i.e. whether they are installed vertically or horizontally.

Blade

These are intended to be lightweight but strong in terms of durability and reliability. Sealed by caps at both ends they are made of guage blades.

Cellular

These bolted cells compel the droplets to drift into various directions. By undertaking this, a force is created at the center. The drift is kept far away from the wet stream of gasses, using force which was created in the process beforehand.

Cassette

Cassette is a lightweight yet robust design. Removal and lifting is made easier by the cassette. It not only possesses a longer lifespan but is preferably made use of in retrofitting.

Fill-integrated

The lifespan of a drift eliminator is enhanced by integrating innards like that of carbon black, inside the core material. The use of fillings prevents the corrosion of primary material.

Resources made use of in the making of eliminators.

Here is not much variety in terms of the materials used in the construction of drift eliminators. Think of it as a blessing in disguise since it makes selecting one easier yet promising as each material has its own unique characteristics.

Polyvinyl Chloride (PVC)

This is the most frequently made usage of material in drift eliminators. Not only are they the cheapest and the most affordable option available but are also practical since PVC eliminators are resilient to erosion.

Polypropylene (PP)

PP is a recyclable material that can tolerate heat better than Polyvinyl Chloride, and is made of plastic and fiber or either both.

Metal

Steel eliminators prove ideal in conditions including high temperatures or container shipments because of their robust and durable nature. The only complication is that metal is vulnerable to weathering, but this too can be solved with a covering for preservation.

The Ideal Features to look for in a Drift Eliminator

Choosing the right kind of eliminators can be a difficult process considering the fact that there are a lot of models and designs present in the market. To make selecting the one that best suits your needs from the pointed options easier and quicker.

The following list can be used as a checklist to select the best one for yourself.

- These eliminators have certifications which grantee that they are safe to use.

- Reliable to use and have a high durability.

- Drift loss of up to 0.01% can be maintained by a drift eliminator.

- Efficient performance by the machine.

- Cost-efficient.

- Adaptable and bendable for alteration.

- The process flows through easily.

Whichsoever model meets the most, if not all or at-least some can ultimately be the one that suits you.

An Essential Industrial Product

Drift eliminators are a very important part of cooling towers. For better results the worn out drift eliminators must be replaced with new ones if they have been in use for a significant number of years.

The assistances that organizations obtain with conserving towers can get after them, it is fair to say that drift eliminators are undoubtedly an essential industrial product.

Promoted