5 Industries That Can’t Do Without Custom Machining

Precision and efficiency have become the leading demands for manufacturing. Modern equipment is rapidly changing.

New, sturdier and harder materials are used, complex geometries with tight tolerances and fine surface finishes are required and all of that has to be done at a faster pace.

This race toward product perfection involves using professional custom machining services for more and more industries for a lot of different purposes. Let’s see, which modern industries simply can’t manage without custom machining.

What is Custom Machining?

First of all, we need to specify this “custom” word. What’s the difference between custom and general machining?

General machining is usually used for mass production, for example, in cases where high precision of some surfaces must be achieved, while the majority of the surfaces is made by casting or forging a blank.

In those cases, large volumes of the same part are manufactured. The waste is much lower and the cost per part as well.

But what if you need a unique new sample component? Preparing a wholesome production of it will be very expensive but you could just buy a big lump of the metal alloy you need – usually comes in cylinders or cubes, not actual lumps – and cut off all the unnecessary bits.

The scrap rate will be much bigger but the overall cost of the component will be much lower, as well as the time required for production.

Medical Industry

Medical industry is one of the examples where custom machining is simply indispensable. Medical industry deals with people and we are all unique. A prosthesis that fits one person will probably be useless to another.

Apart from that, high precision is required from medical tools. If a substitute leg is even a few mm off longer than the real leg, eventually, the client will have a lot of back pains.

And that’s the least of the trouble, some operations require bones to be swapped with metal components. Even a small deviation will bring discomfort to the patient.

Another issue is the fact that the medical industry has to work with titanium a lot because of its great biocompatibility and strength. However, it’s very hard to process. Only the hardest cutters can manage.

Aerospace Industry

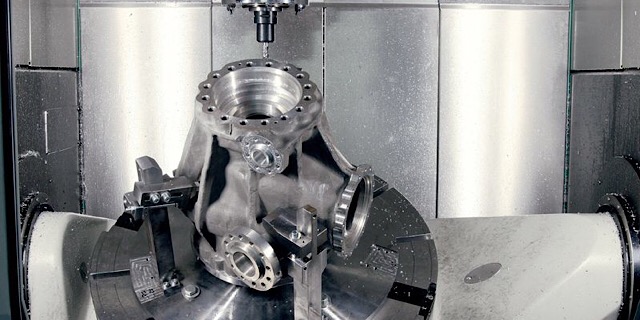

Aerospace is one of the most complex industries in the world. Not only is the geometry of aerospace parts mind-boggling often as not, but they also work under severe stresses.

The overloads, the jet fighter parts withstand when it does all those cool aerial aces is terrifying. Not only that, but the design must aim at having as little weight as possible, otherwise the plane will be too slow and will require too much fuel.

So, airplane parts are made with tolerances ranging in single-digit microns. Aerospace parts must undergo severe experimental tests in order to be confirmed for actual flights but the quality of the examination samples must remain the same as it is for actual parts.

So, aerospace manufacturers with their inflexible mass production factories often hire custom machining services for design validation prototypes.

Automotive Industry

The automotive industry heavily relies on its customers. That’s why aesthetic looks and issuing newer better models is very important.

However, cars contain people and their components must undergo multiple verification tests for certification. Custom machining offers outstanding surface finish for aesthetic elements such as spoilers, wheel disks and so on, and rapid manufacturing offers rapid prototypes at very short notice.

Statistics suggest that manufacturers who employ custom machine shops take 10 percent less time to develop a new car and save on machining costs.

Power Industry

The power industry is quite similar to the aerospace industry. They both have a lot of complex parts made of expensive alloys with intricate geometries that have to be manufactured to very close tolerance.

Gas turbines are especially hard to manufacture since they work under the highest temperature and pressure. Since power equipment isn’t changed as often as cars or airplanes, making new models is not the main issue.

However, custom machinists can find work here as well. The opposite happens often: turbines serve for such a long period of time that all the spare part kits for them have been depleted and are out of production by the manufacturer.

In this case, the task is even harder than making a rapid prototype – rapid because power units’ downtime is unimaginably expensive and can result in electricity shortages, which is a breach of safety for major cities.

You have to reverse engineer the existing sample part and then create substitutes. Some CNC machining services offer such jobs but this is another level of custom machining.

Optical Industry

Optical industry deals with different lenses for a large range of different products: cameras, microscopes, glasses, car lights and so on. in order for all of the mentioned equipment to function properly, it needs lenses from transparent materials.

The most common optical materials are glass, PMMA (Plexiglass), and polycarbonate. All of the above must be machined to the needed curvature and mirror-like surface finish. Personal glasses lens are made like that.

People may have different eyesight in their left and right eyes and would require a custom lens to be manufactured. A fast way to machining transparent clear optical rapid prototypes is diamond tip machining.

The cutter has a single diamond tip with a very fine point that provides the perfect finish if machining is carried out with great speeds and a minimum feed rate.

Profiting from Precision

It’s safe to say that all the major industries profit from custom machined parts and rapid prototype machining. Those services offer better flexibility, shorten product lead time, cut manufacturing costs, and improve overall product quality.

Precision machining can be put to good use in multiple industries and thus, flexible custom machining shops can prosper by taking orders from a lot of different fields and manufacturing verification prototypes and test samples for those enterprises.

And the enterprises will prosper because they won’t have to worry about resetting their mass production tuned plants for small-batch manufacturing.

Promoted