Sick demonstrates ‘smart logistics’ system for warehouse automation

Sensors supplier Sick showcased a new “smart logistics” system at the recent ProMAT Show, one of the world’s largest material handling exhibitions.

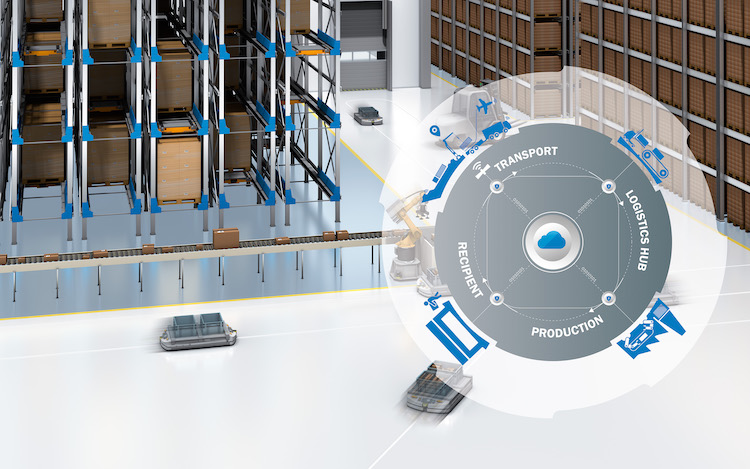

Sick says its system demonstrates how to obtain greater efficiency throughout supply chain operations.

Sick presented its new innovations under the banner of “Logistics Gets Smart”, and says they are designed to provide “highly efficient solutions for intralogistics applications”.

The company says the flexibility in production and logistics has been made possible by sensor intelligence, and its features include:

- programmable and self-learning cameras;

- reliable safety sensors for human-robot collaboration;

- reliable track and trace systems on conveyors; and

- state-of-the-art package analytics software to monitor performance.

All these devices are connected with one another via the cloud, implementing Industry 4.0 connectivity along the entire value-creation process.

In complex warehouse systems, sensor solutions ensure optimum storage space assignment and accident-free handling by transport shuttles.

Integrated cameras and photoelectric sensors automatically detect objects, monitor possible overruns, and position the shuttles precisely in front of shelf bays.

This keeps everything safe and efficient, says Sick.

The Package Analytics software from Sick also offers the possibility of monitoring systems and keeping an eye on their performance.

This ensures traceability and also allows the accuracy and efficiency of sorting processes to be improved – whether on a conveyor belt, in a freight center or in the overall network.

When Logistics Gets Smart, flexibility is an added benefit, says Sick.

The supply chain is taken over by driverless transport systems, whose autonomous navigation is shown live, together with collision prevention solutions.

The data from all the sensors in the smart factory are evaluated on a large display giving visitors a constant overview of logistical and production processes as well as key performance indicators.