B&R offers new possibilities with digital twins

B&R Automation claims to have simplified model-based machine development with its new B&R MapleSim Connector, claiming it considerably reduces the time spent modelling machine components, with machine functions being easy to program and deploy.

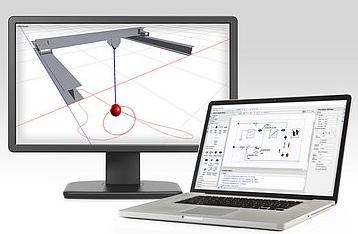

B&R MapleSim Connector is integrated in the B&R Automation Studio environment and makes it efficient for B&R customers to integrate the MapleSim tool from Maplesoft.

MapleSim creates a highly accurate, dynamic model of the machine based on CAD data in STEP format. All forces and torques are modelled with great precision, allowing the model to be used as a digital twin for component sizing.

The physical model is also available as a functional mock up unit for virtual commissioning of the machine software in Automation Studio. This helps avoid the risk of design errors.

B&R MapleSim Connector offers two export functions for efficient use of digital twins in the development process.

On the one hand, it is possible to export simulation data to optimise the sizing of servo drives, motors and gearboxes using tools like ServoSoft, on the other,, the model built in MapleSim can be exported as an FMI file, including the CAD data.

The model built in MapleSim can be used as a simulation model in Automation Studio and transferred directly to the B&R control hardware.

The result is hardware-in-the-loop simulation, where the machine’s behaviour is emulated in real time to create a controlled environment where the machine software can be tested safely.

In this environment, all control parameters can be manipulated and the temperature behaviour of the drive can be simulated. The behaviour of the digital twin is visualised live in B&R Scene Viewer.