IMTS: Universal Robots to showcase its new e-Series collaborative robot for first time in the US

Universal Robots is planning to showcase its new e-Series collaborative robot for the first time in the US at the IMTS industrial technology event.

The company says the new e-Series “sets a new standard for collaborative robots”, adding built-in force/torque sensing, “unrivaled” safety features, and improved precision for faster integration in a wider range of future-proofed applications.

Universal Robots is widely belived to have pioneered the collaborative robot and continues to evolve its ground-breaking, collaborative automation technology with the introduction of this new “flagship line”, the e-Series cobots.

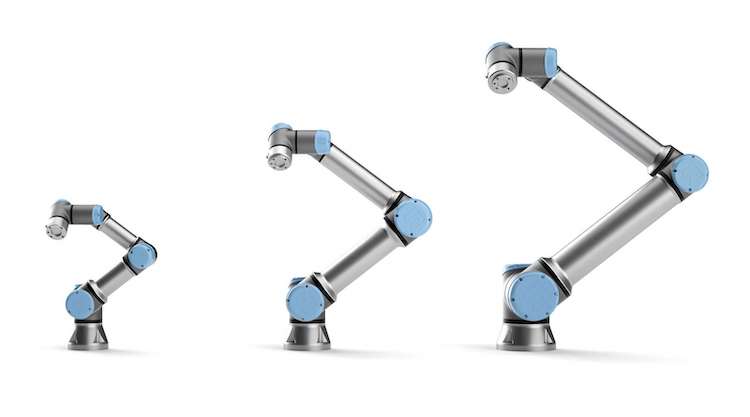

The new UR3e, UR5e and UR10e robot arms will launch in North America at IMTS in Chicago, September 10-15 at Universal Robots’ IMTS booth N-236861.

Stuart Shepherd, regional sales director for Universal Robots’ Americas region, says: “The e-Series strengthens the core principles that define collaborative robots: fast set-up, easy programming, flexible deployment, safe operation, and a quick return on investment.

“As manufacturers increasingly embrace cobots, we see the need to support even more demanding applications with the greater accuracy and tool integration of the e-Series.”

With a new built-in, tool-centric force/torque sensor, the e-Series is capable of popular collaborative robot applications that require force control “right out of the box”, such as sanding, buffing, polishing and deburring where force-feedback is paramount in order to obtain uniform results.

Additionally, the force/torque sensor can be used to measure mass and perform inspection processes or precisely detect contact.

Increased repeatability of 30 microns (0.03mm) in the UR3e and UR5e models and 50 microns (0.05mm) in the UR10e makes the new cobots suitable for precise finishing, assembly and electronics tasks.

A re-designed intuitive and responsive touch user expedites program development by reducing programming to a few clicks on a new lightweight, wide-screen teach pendant.

At the same time, advanced users can utilize the new externally accessible 500Hz system bus to implement more complex motion control algorithms or profiles, such as advanced machine vision applications.

The user interface now also includes the ability to program stopping time and stopping distance for protective stops.

This “unique” feature, which Universal claims is “not found on any other collaborative robot”, greatly reduces the complexity and uncertainty involved in performing pre-deployment risk assessments.

All 17 safety functions are certified by TÜV Nord and comply with the latest ISO machinery safety standards for unobstructed human-robot collaboration.

The “e” in e-Series stands for “evolution” and underpins Universal Robots’ key vision of “Empowering People and making it Easy for Everyone”.

“End-users with complex applications and diverse or uncertain future needs will benefit from the e-Series platform and our unique UR+ ecosystem knowing that their investment will be able to grow with them as their needs change,” says Shepherd, referencing the rapidly expanding portfolio of certified UR+ plug & play end-effectors, software and peripherals certified for UR cobots now available.

As the catalog and capability of UR+ products grow so has the need for increased tool power consumption.

To address this emerging need the e-Series platform tool power supply now supports up to 2A of peak current.

The new cobot line also adds four additional digital inputs with an associated interface for use with conveyor tracking.

A new wrist-joint-tool communication interface reduces production line integration time and the hassle associated with routing cables between the end-effector and control cabinet.

All joints are field replaceable in under six minutes, says Universal.

“The global cobot market is the fastest-growing segment of industrial automation. The e-Series will continue to propel this class of robots forward into new applications in small machine shops and large enterprises alike. I look forward to introducing the IMTS audience to the e-Series experience,” says Shepherd.

Universal Robots will start taking orders for the e-Series immediately and plans to begin shipping units to customers from August 1, 2018.

IMTS will be the first opportunity in North America to experience the e-Series live.