Computers on wheels: An insight into how computers are making cars in their own image

When Robotics and Automation News interviewed Professor Ralf Herrtwich, the boss of autonomous driving technology at Daimler Mercedes-Benz, one of the many interesting insights he gave us was about the nature of car making these days.

Herrtwich said that, while building cars is still mainly a mechanical process, developing them is overwhelmingly about software.

“Both at OEMs (original equipment manufacturers) and suppliers,” said Herrtwich, “software engineering and coding constitute a huge and ever-growing portion of the work.”

This suggests that the big automakers are far more capable when it comes to computing technology than many people might think.

When companies like Google and, more recently, Apple talk about developing driverless car technology, some might think it means the end of the traditional automakers’ dominance of the market.

They may have thought that if cars are becoming computers on wheels, as many people think they are, then it seems natural to think the Silicon Valley tech companies have an enormous advantage.

That may well be true in some areas, but building physical machines that move is still far more complex than building software that lives inside computer systems.

The two sectors are, of course, converging – with materials science finding itself at the centre – but it is by no means a foregone conclusion that one side will dominate the other.

What seems to be happening is partnerships are being formed between the big companies and the smaller startups are being acquired.

So, Google has licensed its driverless car tech to Fiat Chrysler, while Apple has provided its in-car entertainment and communications interface to a host of others.

Below, we highlight some of the more interesting developments in this space where the technologies in automotive, telecommunications and computing are converging to create a completely new kind of driving experience.

While some people would never even consider allowing themselves to be driven by an autonomous car, many others are getting used to being in cars that already have a large amount of self-driving technology, which is currently packaged under the label of “advanced driver assistance systems”, or ADAS.

ADAS can mean anything from cruise control to self-parking, all of which needs computing. So, as Herrtwich observed, while the engineering designers continue to build more sleek looking car bodies, the coding not only continues but becomes ever more important.

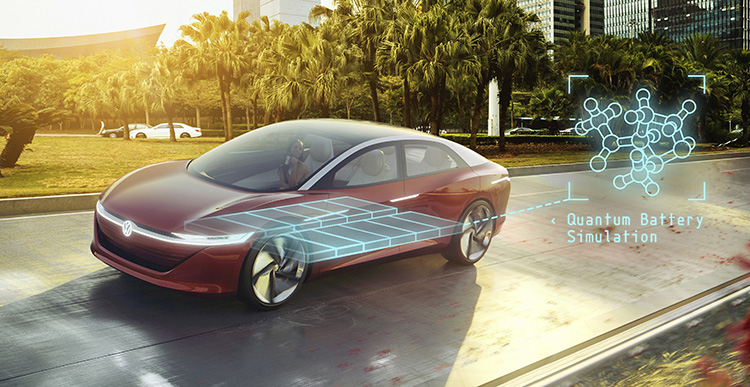

Quantum geekery

When automaking giant Volkswagen Audi bought a quantum computing system from D-Wave last year, it was probably thought of as an experiment or just a way to keep tabs on what might eventually become an important technology in the future.

Many experts argue that quantum computers are decades away from being commercialised for the mass market, but Volkswagen claims it is already using the D-Wave quantum computer to design more efficient, more powerful batteries for electric vehicles.

D-Wave computers cost a minimum of $15 million, so Volkswagen probably feels it must show that it is at least doing something with its investment.

In this instance, the story Volkswagen is pushing is that it has become the first company or group to have “succeeded in simulating industrially relevant molecules using a quantum computer”.

The aim of the project is to develop a “tailor-made” battery for high-performance electric vehicles.

But quantum computing – on which VW is partnering with Google to further develop – is just one part of a broader move towards using more computing in general.

Carmakers like Volkswagen Audi have always relied on supercomputers to help design and simulate prototypes, and this reliance will only increase, although it may eventually be supercomputers built using quantum processors.

But it’s not only about specific areas of the automaking process, companies like Volkswagen Audi – as well as industrial companies of all types – are increasingly making their entire process digital, from shop floor to administrative office.

Martin Hofmann, chief information officer of Volkswagen Group, says: “We are focusing on the modernization of IT systems throughout the Group.

“The objective is to intensify the digitalization of work processes – to make them simpler, more secure and more efficient and to support new business models.

“This is why we are combining our core task with the introduction of specific key technologies for Volkswagen. These include the internet of things and artificial intelligence, as well as quantum computing.”

But going back to the drawing board, one of the most time-consuming activities in any research and development centre must be the testing of many different variations of an idea.

The people who eventually gave the world the light bulb probably tried hundreds of different materials before eventually deciding on one that would be able to glow without melting for a long enough period of time that made it commercially viable.

Similarly, all the new materials and processes that are emerging now need to be tested one by one to see which ones can help solve the issues facing engineers. And some people say quantum computers can help accelerate that process.

Florian Neukart, principle scientist at Volkswagen’s Code Lab in San Francisco, says: “We are working hard to develop the potential of quantum computers for Volkswagen.

“The simulation of electrochemical materials is an important project in this context. In this field, we are performing genuine pioneering work.

“We are convinced that commercially available quantum computers will open up previously unimaginable opportunities. We intend to acquire the specialist knowledge we need for this purpose now.”

My other car’s a digital one

Digitalisation is a huge trend. It’s huge because, well, the world is huge, and has a huge number of components and elements.

And if you’re going to get into the physics of everything – all the minute details right down to the molecular level – you’re going to need a bigger computer and more powerful software.

All the main software companies in this space – Dassault Systèmes, Autodesk, Ansys and others – offer simulation capabilities, but it’s probably worth highlighting a few here since they are relatively new and being improved all the time.

Ansys recently launched a new version of its software which it claims offers the “first comprehensive solution” for simulation-based digital twins. (See story.)

“Digital twins”, as you probably could have guessed, refers to digital versions of real-world things, whether those things are molecules of a material or components or complete systems.

Ansys may be best-placed to grow its market share in the engineering design space this year if the use of simulation software continues to grow because it probably the company most strongly associated with engineering simulation. Some observers say 2018 will see particularly strong growth in engineering simulation software growth.

Dassault Systèmes is a provider of software that is widely used in the automotive sector and many others. Among the many applications it offers is something called Simulia, which, as the name suggests, is the company’s simulation offering.

Based on the company’s 3DS platform, Simulia is said to provide “realistic simulation applications that enable users to explore real-world behavior of product, nature and life”. The company also offers SolidWorks Simulation.

One of the key industries Dassault Systèmes is targeting – as well as automotive and aerospace – is the medical sector, where drug testing and development would seem to offer many opportunities.

Autodesk is still strongly associated with architecture because of what used to be its flagship product, Autocad.

But as the engineering and manufacturing sector discovers the company’s many new applications – some of which were added recently through acquisitions – Autodesk’s image may change.

Autodesk has a number of specific simulation applications which it offers as part of its suite. Autodesk’s simulation software range includes Nastran, which was developed by Nasa and is used for finite element analysis, and Helius, which is used for the design of composite materials.

Out of memory

In order to run such powerful software processing such large amounts of data, you’re going to need big computers.

The one on your desk might be enough – depending on what you want to use it for.

But we’ll take a look at the options another time – whether it be cloud computing, supercomputers or, if you’ve got $15 million to spare, a D-Wave quantum computing system.