Nexteer launches new auto design and manufacturing system

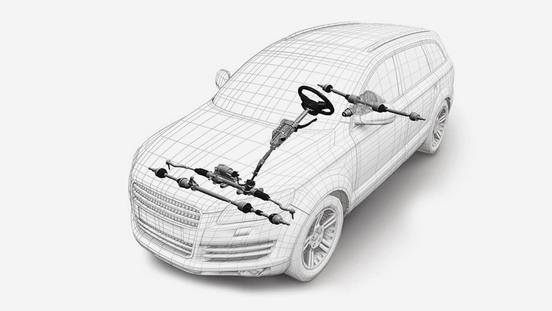

Nexteer Automotive has introduced Digital Trace Manufacturing, which it claims is one of the most advanced, holistic, integrative approaches to design and manufacturing systems ever seen in the auto industry.

The system uses the latest technologies and data analytics within one common, global architecture. For customers, this will help deliver high-quality product performance while boosting value and global capacity optimization across all of Nexteer’s 24 manufacturing locations worldwide, claims the company.

Nexteer is currently showcasing its industry-leading process automation systems during the 2018 North American International Auto Show in Detroit.

Using virtual reality, guests can experience firsthand how Digital Trace Manufacturing integrates workstation optimization as part of a greater effort to improve processes.

“To enable Digital Trace Manufacturing, we’re using a connect-the-dots approach, in which the thousands of data-producing dots around the world are standardized and talk to one another.

“Each dot represents a machine, process, database, document, workplace robot and so on,” said Dennis Hoeg, vice president and North America chief operating officer.

“When the dots are connected, the result is one common, global architecture. Digital Trace Manufacturing allows Nexteer to deliver a dynamic, comprehensive view of its manufacturing operations in real time, which is a big payoff for our customers, employees and shareholders.”

Digital Trace™ Manufacturing gives Nexteer a more intimate understanding of its global operations at any given minute. Furthermore, any improvement in design or production made at one location can quickly be replicated globally.

According to Hoeg, the difference between what Nexteer is doing and what is commonly referred to in the industry as ‘digital thread’ or ‘manufacturing automation’ is the vastness of what Digital Trace Manufacturing is covering.

Because of the scope and the level of integration, it will take several phases to fully implement the entire system, Hoeg explained. However, he has already seen a positive impact on customer responsiveness and quality in the initial phases.

Ultimately, Digital Trace Manufacturing helps quality engineers proactively confirm product quality early in the process, potentially eliminating the need for costly end-of-line testing.