Aerotech demonstrates patent-pending motion control sensor

Aerotech has launched a motion control sensor with a parallel-kinematic design which provides unmatched geometric performance, says company, adding that it also offers superior positioning resolution and linearity with the direct-metrology capacitive sensor.

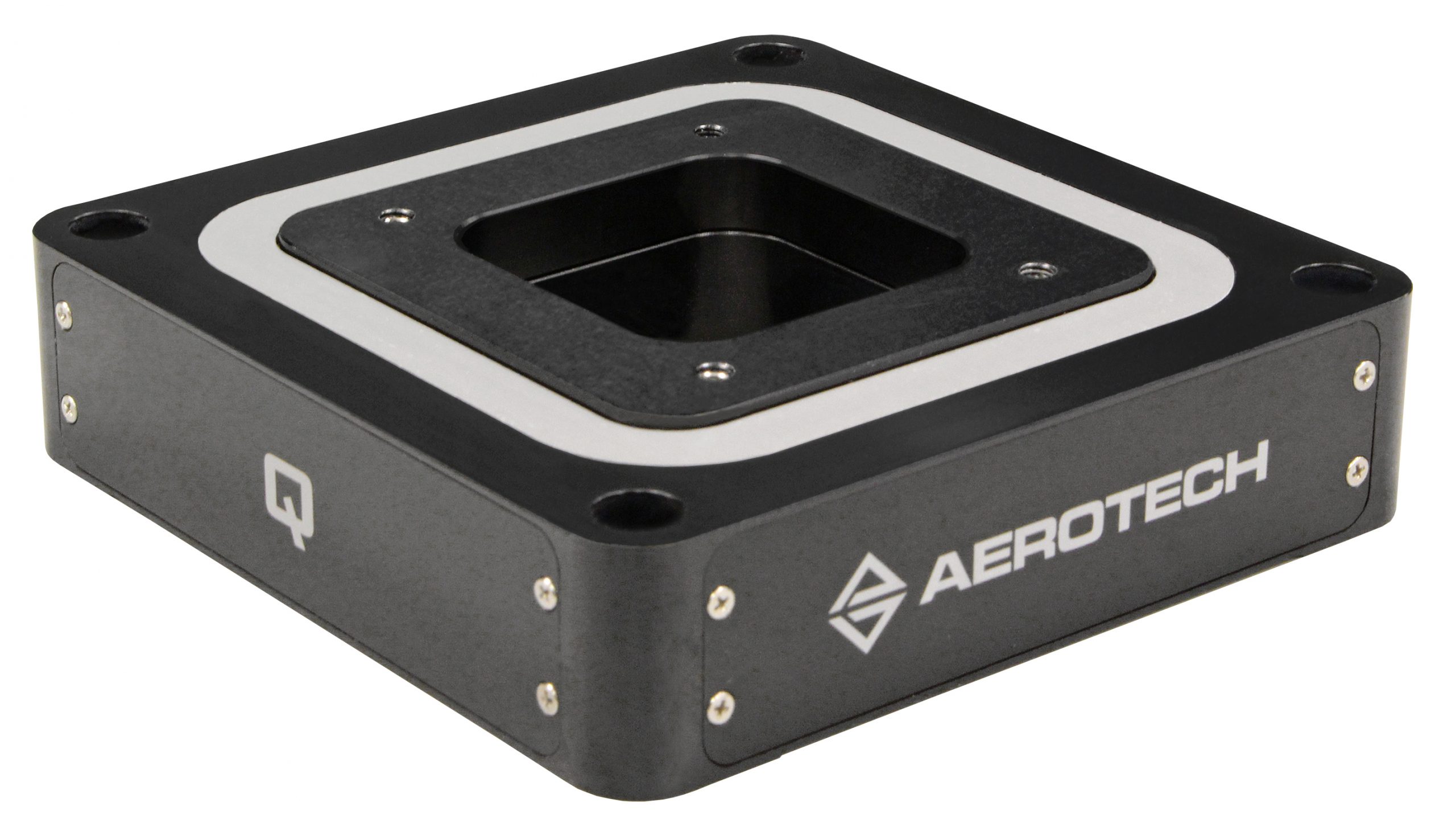

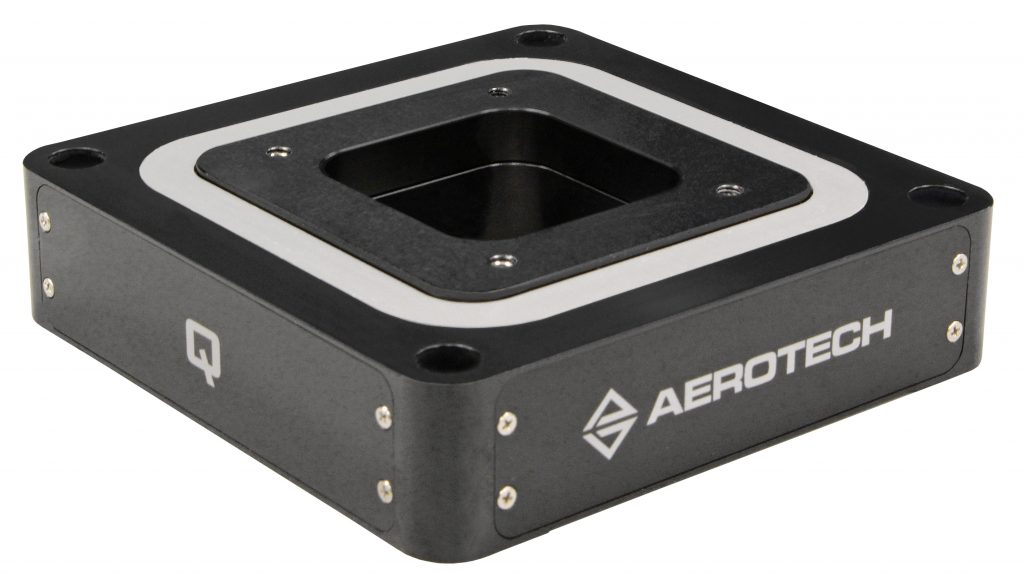

Aerotech’s QNP3 series XYZ piezo positioning stages combine sub-nanometer resolution, high dynamics, and excellent geometric performance in a compact three-degree-of-freedom (DoF) package.

They come with a 40 mm x 40 mm clear aperture with closed-loop travels up to 100 µm x 100 µm x 10 µm (open-loop travels to 120 µm x 120 µm x 12 µm).

The design is ideal for optical and scanning probe microscopy or other inspection or manufacturing applications where two-sided part access is required with three-DoF manipulation.

Precision parallel-kinematic design

QNP3 piezo stages use an FEA-optimized precision parallel-kinematic flexure and metrology design to ensure superior multi-axis accuracy, high stiffness, and long device life. High stiffness and resonant frequency enable high process throughput and fast closed-loop response.

The patent-pending drive design minimizes X and Y yaw errors while still maintaining an Abbe-compliant metrology system. This design results in unmatched positioning performance over the entire XY travel space.

Z-axis actuators and capacitive sensors are designed to provide Abbe-compliant feedback in the vertical direction with minimal geometric errors.

QNP3 stages are available with closed or open-loop feedback. The unique capacitive sensor parallel-metrology design directly measures the output of the positioning carriage, delivering sub-nanometer resolution, linearity errors better than 0.01%, and single-digit nanometer repeatability.

When coupled with Aerotech´s Q-series controllers and drives, QNP3 stages demonstrate sub-nanometer positioning resolution and in-position stability (jitter) while maintaining high positioning bandwidth.

Advanced software options, such as Dynamic Controls Toolbox and Motion Designer, provide a variety of highly-effective, easy-to-use tools including Iterative Learning Control, Harmonic Cancellation, and Command Shaping, providing improved tracking errors and faster step-and-settle times. OEM drive options are also available.

An optional mounting plate provides direct mounting to English or metric breadboard optical tables. A solid tabletop is also offered. QNP3 piezo stages are available in custom materials, and in vacuum-prepared versions, upon request.