Connected asparagus: Bosch outlines vision of a future with connected factories and robotic farmers

One of the world’s largest engineering companies, Bosch, has outlined its vision of the future, which includes a world full of smart factories, robotic farmers and connected asparagus.

Bosch made its views available to Robotics and Automation News in a series of documents sent to us this week.

The company believes two main areas of technological development stand out from the rest: connectivity and sensors.

Intelligently connected workstation ensures faster familiarisation

Bosch says the connected factory is “finally a reality”. One of the aims of the company’s research and development is to boost productivity in industrial manufacturing with its Apas products.

Bosch claims the Apas robot is “the first collaborative robot to be certified as an assistance system”. The new Apas workstation (main picture) has recently joined the product range.

The “intelligently connected workstation” combines a work surface, a collaborative robotic arm, and a monitor that displays work instructions.

Bosch says that because of its “sensitive sensor skin”, the robotic arm immediately stops whenever people get too close. “People and machines can therefore work together without a protective barrier,” it says, adding: “As a result, the system creates new possibilities for teamwork between machines and associates.”

The employers’ liability insurance association has certified the Apas as safe for direct collaboration with people.

Sensors improve logistics through real-time information

Information provided in real-time also helps to improve logistics. Bosch’s sensor solution known as “TraQ” (for “track quality”) monitors supply chains.

To this end, sensors in the packaging or on the product itself record quality-relevant information during transport – such as temperature, vibration, light, and humidity levels – and send it to the Bosch IoT Cloud . A Bosch software application in the cloud compares the readings from the sensors with permitted levels.

If there is a deviation from one of these, customers, suppliers, and service providers are notified and alerted in real time.

This benefits the transport of sensitive goods, such as semiconductors and delicate laser technology.

The connected transport box detects vibrations that are too strong and reports them to the owners and insurance companies. As a result, it is possible to directly determine the point at which the damage occurred and what caused it.

If the delivery of machine parts is delayed, the customer can still make other arrangements. The benefit of this, according to Bosch, is timely notification minimises costly downstream consequences, such as production stoppages, in case of damage to goods.

Bish, bash, Bosch

While 130-year-old Bosch is regarded as a traditional engineering company, and probably the largest supplier of automotive parts in the world, it’s obviously working on some interesting developments in the area of advanced robotics and automation in new growth areas.

As well as collaborative robotics, as mentioned above, another of Bosch’s more interesting developments is in agriculture.

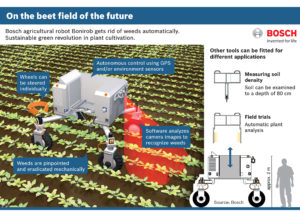

For this sector, Bosch has built a new product it calls the “Bonirob agricultural robot”.

Bonirob won’t get lost

Bosch says Bonirob is a smart agricultural robot which can find its own way around the fields and automatically analyse plants.

Bonirob is about the same size as a compact car, and uses video- and laser-based positioning as well as satellite navigation to determine its exact location. “It knows its position to the nearest centimetre,” says Bosch.

With the help of cameras and computer-based image analysis, it recognizes and classifies plants. This is especially useful for plant breeders, who have to painstakingly analyse thousands of plants for plant size and colour, fruit size and form, and insect damage.

Based on these findings, the human plant breeders can then decide which plant strains are worth pursuing further.

The Bonirob is named after this plant appraisal process, which is known in German as “Bonitur”. This automatic screening, says Bosch, will “save significant time and effort”.

Bonirob doesn’t need pesticides

Bonirob does more than just speed up the plant-breeding process, says Bosch. On the basis of leaf shape, it can distinguish between crops and weeds. With the help of a precisely controlled rod, it gets rid of weeds mechanically, rather than with weed killer.

Undesired plants are swiftly rammed into the ground. Bosch says experts have praised the idea of equipping the robot with modules for different tasks. Such modules, or “apps”, are available for tasks such as measuring soil density, mechanical weed removal, and plant breeding.

In September 2016, Germany’s minister for food and agriculture, Christian Schmidt, presented the agricultural robot with the “Deutscher Innovationspreis Gartenbau”, a national award for innovation in horticulture.

That connected asparagus we mentioned

Bosch has also developed a radio sensor for better asparagus yields. Named “Deepfield Connect – Asparagus Monitoring”, the sensor measures the temperature in the beds where the vegetable is grown and transmits it to farmers’ smartphones.

Farmers can use this data to track the temperature changes of their crops in detail and optimize the growing conditions. The system saves time and money, as farmers need to visit their fields less frequently.

Try ploughing the fields with your smartphone

Asparagus grows especially well between 18 and 22 degrees Celsius. One way farmers maintain this temperature is by covering the mounds with strips of two-sided foil: one side is black, the other white.

To heat the mounds using sunlight, the foil is laid with the black side facing up. To cool them when it gets too warm, the foil is laid with the white side facing up.

The Bosch solution consists of several sensors embedded at various depths in the ground to measure the temperature.

Cables send the temperature readings to a small box, which transmits the data via radio to a cloud that is based on the Bosch IoT Suite.

From there the data is routed to an app on the farmer’s smartphone.

Bosch says its IoT Suite is a “comprehensive software solution” that can be used to develop, provide, and operate applications in the internet of things.