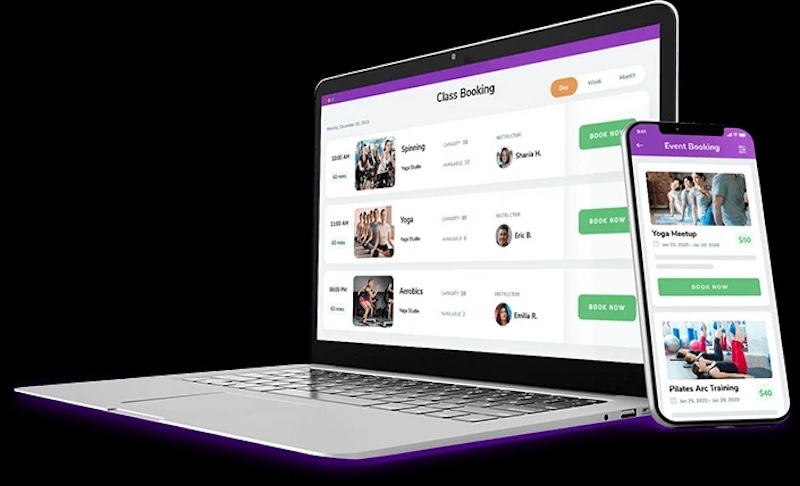

The Benefits of Using an Online Booking Software Tool

November 23, 2023

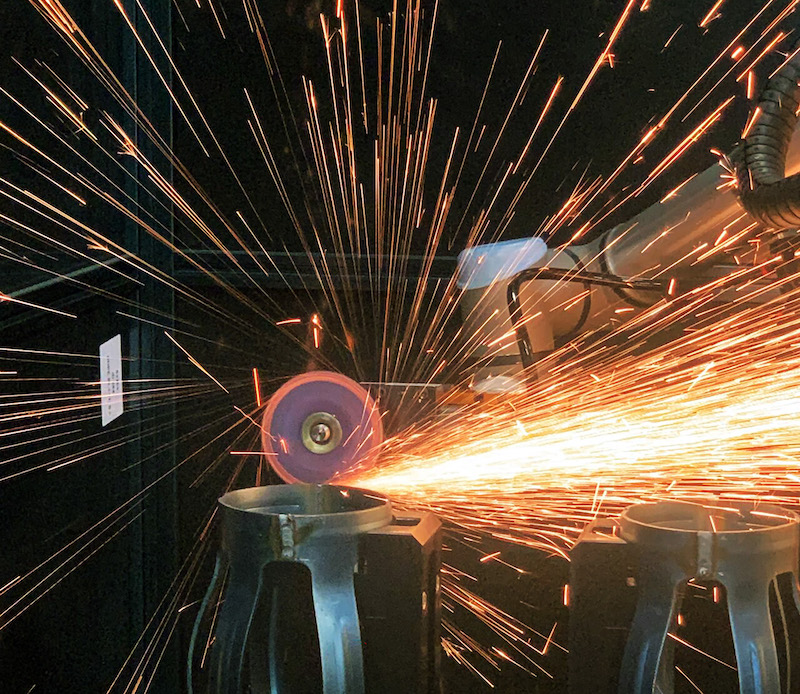

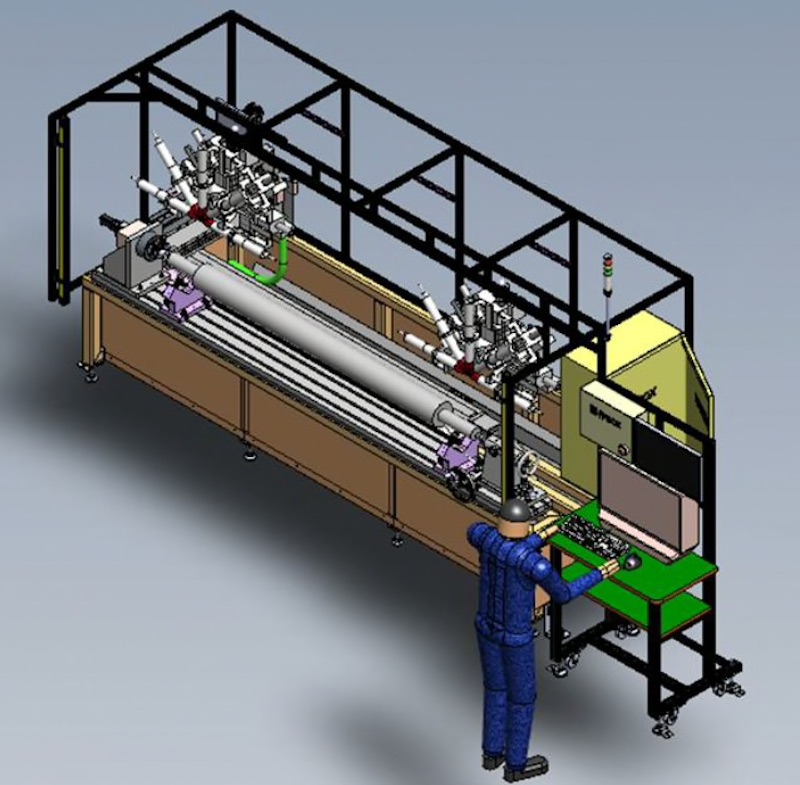

Carbon Robotics adds LaserThinning capability to its LaserWeeder

February 13, 2023

How Can Education Websites Get More Traffic

January 11, 2023

No-Code Automation Testing Guide

December 26, 2022