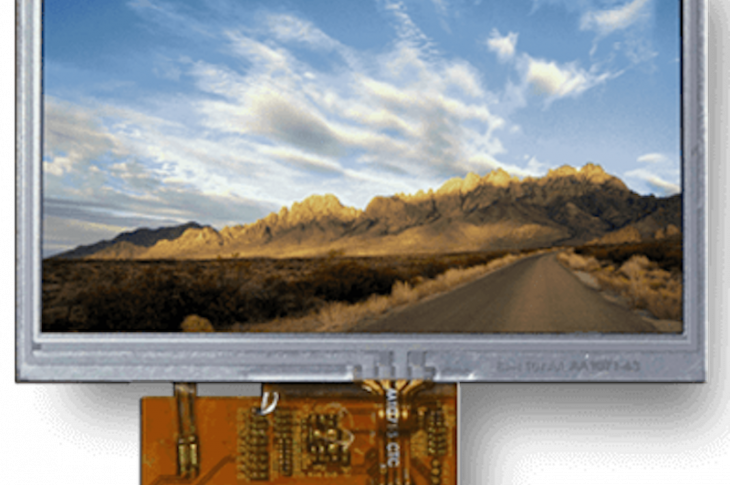

How to Apply Color LCD Displays in Industrial Settings

April 23, 2024

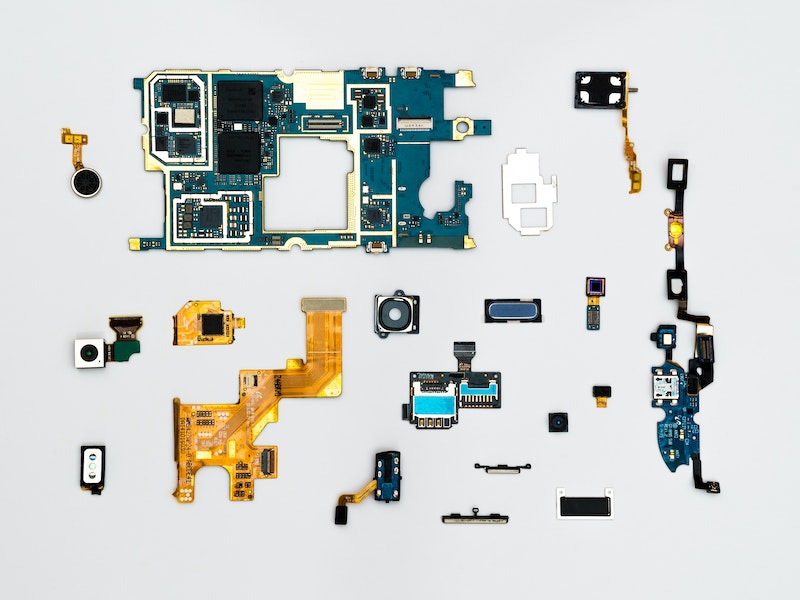

Tips for Maintenance of CNC Lathe Machines

March 21, 2024

Benefits of S1000D Conversion

January 30, 2024

The Role of AI Predictive Models in Autonomous Robotics

October 13, 2023