Unlocking the Potential of Automation: A Deep Dive into Air Bearings

September 14, 2023

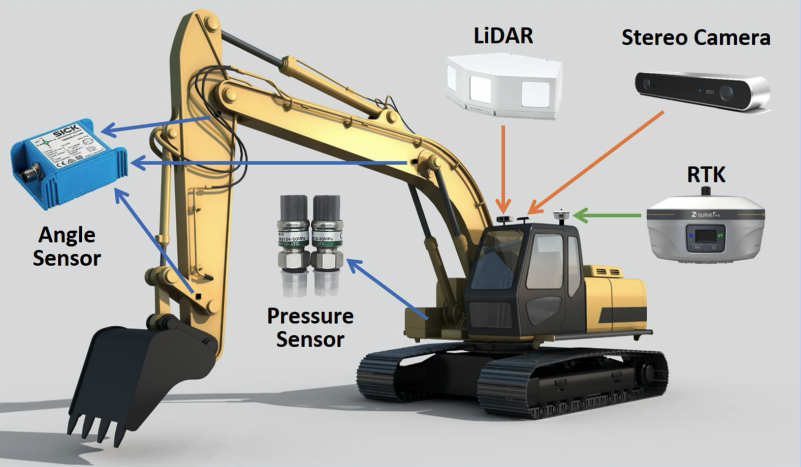

SRI unveils autonomous digger for construction sites

August 24, 2022

Murata expands AGV range, partners with AGVE Group

March 28, 2022

5 manufacturing trends to look forward to in 2021

September 7, 2021

6 Engineering Tips When Designing Machinery

July 26, 2021