Tips for Designing Timeless User Interfaces for a Medical Device

December 13, 2023

Benefits of Hiring a Product Design Consultancy for Your Business

December 1, 2023

Transforming Your Basement into a Dream Space

November 23, 2023

TXI lends weight to America’s ‘Titanium Economy’

October 13, 2023

Startups in the Robotics Industry

October 13, 2023

Step-by-Step Guide to Creating a Memorable Logo Online

October 1, 2023

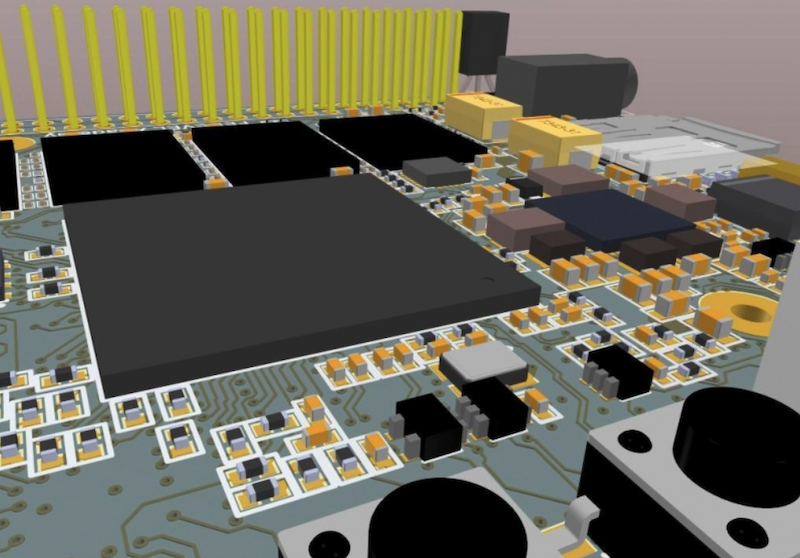

New RoboDK software ‘simplifies robot programming by demonstration’

September 28, 2023