Application of Slip Ring in Industrial Robot

August 20, 2021

How are industries using robots?

August 20, 2021

ABB to acquire autonomous mobile robot maker ASTI

August 19, 2021

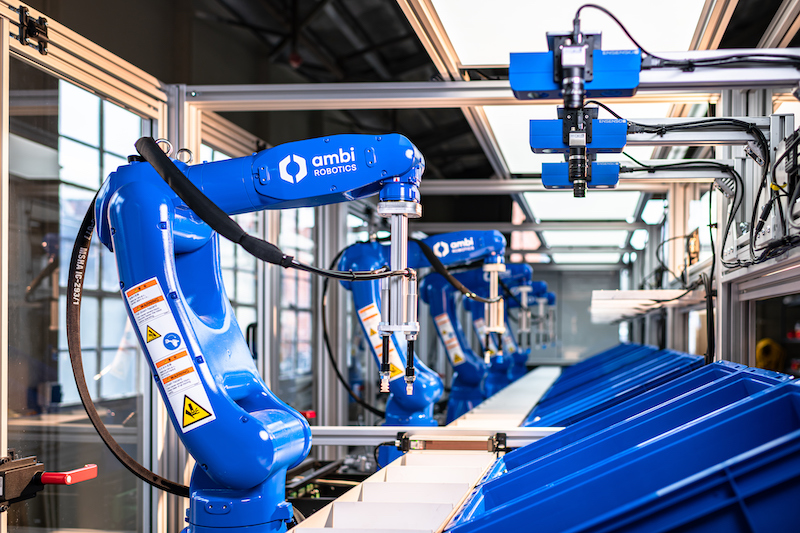

Rapid Robotics raises $37 million in new investment

August 18, 2021

Wyzo the ‘sidebot’ to be showcased at Pack Expo

August 12, 2021