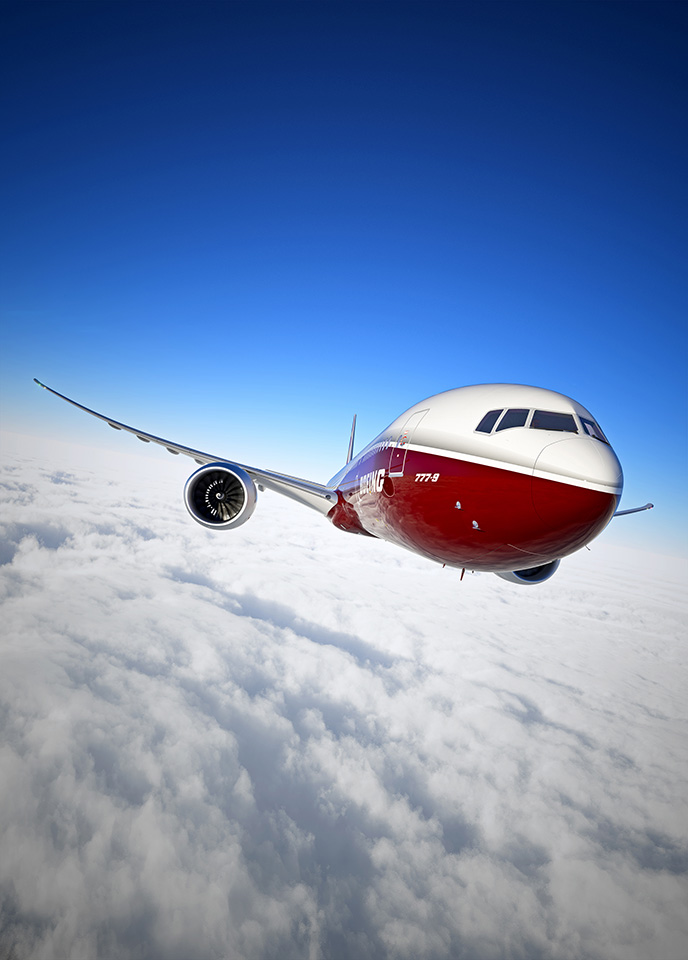

Boeing completes prototype parts for 777X wing at new billion-dollar advanced manufacturing facility

Boeing says it has completed prototype parts for the wing of its new 777X Dreamliner aircraft.

The company is using advanced manufacturing methods, including additive or 3D printing, in the construction of the passenger plane at its new $1 billion Everett, Washington facility.

When completed, the wing for the 777X will be the largest wing Boeing has ever built.

Construction on the 121,000-square-meter building continues, as it will for the next 18 months, with the roll-in of new tools and equipment. And preproduction parts for the 777X are under way.

Nearly 130 mechanics are testing equipment and the first prototype parts, while another 170 employees have moved into the offices so far.

“It’s pretty incredible,” said Brett Miller, a 777X tool engineer, noting that real tools and equipment that previously existed only on computer screens and design reviews are coming together.

The building will support fabrication of the 777X wing, the longest wing Boeing has ever built, and turn the Everett site into a center for advanced carbon-fiber technology.

Production of the first 777X is expected to begin next year. Following flight testing and certification programs, the first delivery is scheduled for 2020. The aircraft’s General Electric GE9X turbofan engines also recently passed two testing milestones in preparation for their delivery to Boeing.

The company has invested more than $1 billion to construct the new facility at Everett. In grand opening ceremonies for the building in May, Boeing and community leaders said the company’s sizable capital investments in the 777X, along with other Boeing programs and capabilities based in the region, will “provide continued jobs and benefits to employees and their communities for years to come”.