Johnson Controls launches ‘unique’ water and energy saving system

Johnson Controls says it has developed a “unique, innovative and industry-leading solution” to help customers address water and energy challenges in facilities through more efficient cooling tower operations.

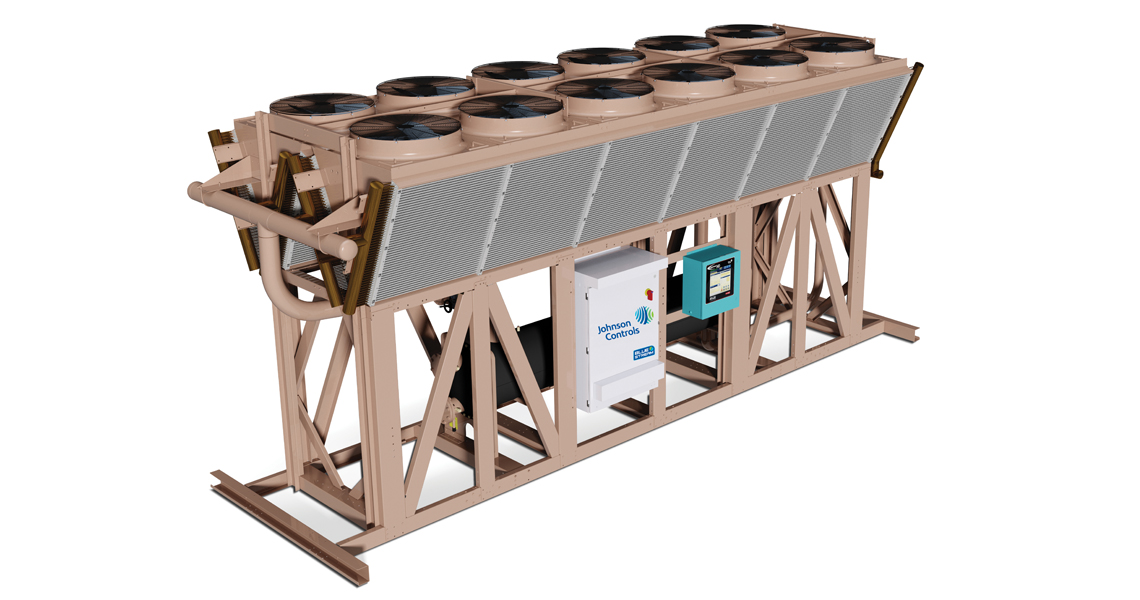

The solution, called the BlueStream Hybrid Cooling System, will be featured at the 2017 Air-Conditioning Heating and Refrigeration Expo in Las Vegas (booth C3124).

Johnson says BlueStream features a groundbreaking technology – thermosyphon hybrid cooling – to reduce water consumption in traditional cooling tower systems by 25 to 80 percent compared to all-evaporative heat rejection systems. It also maintains peak process output and energy efficiency on the hottest summer days.

Like fanning away sweat on a hot day, open cooling towers reduce the temperature of water heated in chillers, industrial processes, data centers and other high-heat practices.

Through a “wet” process, the warm water is sprayed over the fill in a cooling tower to increase the contact area, and the heat is removed through evaporation.

A constant supply of water is needed to replace the water evaporated from the cooling tower, but in many regions, continuing droughts and increasing competition for this essential resource limit water availability.

Additionally, some water is continuously bled from the system to reduce the buildup of undissolved solids as water is evaporated. This generates a large wastewater stream, often containing many additional water treatment chemicals.

Used in conjunction with a traditional cooling tower, the BlueStream system offers “dry” cooling through a thermosyphon process in which refrigerant circulates naturally, with no need for a pump or compressor.

Intelligent, web-connected controls coordinate the operation of both the wet and dry system components and adjust in all weather and thermal load conditions for optimum efficiency, utilizing “wet” cooling when it’s hot and “dry” cooling when it’s not.

“Johnson Controls is concerned about the world’s water resources and how energy and water – the energy-water nexus – are closely linked,” said Clay Nesler, vice president, global energy and sustainability, Johnson Controls.

“Water costs are becoming an increasingly larger component of a heat rejection system’s total operating cost. Drought and water availability can pose a risk for plant and process operations. BlueStream offers a cost-effective way to reduce water use while simultaneously reducing operating costs in heat rejection systems.”

To develop BlueStream, Johnson Controls combined the best technologies in the heat rejection industry. The company worked with the Electric Power Research Institute to evaluate BlueStream in a wide range of cooling conditions in thermoelectric power plants. The project demonstrated Blue Stream’s ability to significantly reduce annual water use in plants while still maintaining peak plant output on the hottest summer days.

In addition, Johnson Controls tested two prototypes – the Energy Department’s National Renewable Energy Laboratory, in Golden, Colorado, and the Water Research Center in Cartersville, Georgia – to validate the dramatic reduction in water consumption provided by BlueStream.

Johnson Controls partnered with NREL and Sandia National Laboratories to install BlueStream at NREL’s 1 MW data center, where it is projected to save a million gallons of water each year.

“Our high-performance computing data center is one of the most energy efficient in the world; however, it is the single largest source of water demand on the NREL campus – so dramatically reducing water use while continuing efficient data center operations is of significant interest,” said David Sickinger, the NREL lead on this project.

BlueStream is an ideal technology for process cooling, data centers, power generation and year-round, base-loaded HVAC applications with water-cooled chillers. Initial analyses indicate a payback period of as low as two-and-a-half years, depending on the facility’s geographic location, utility costs and operating conditions, according to Johnson Controls.