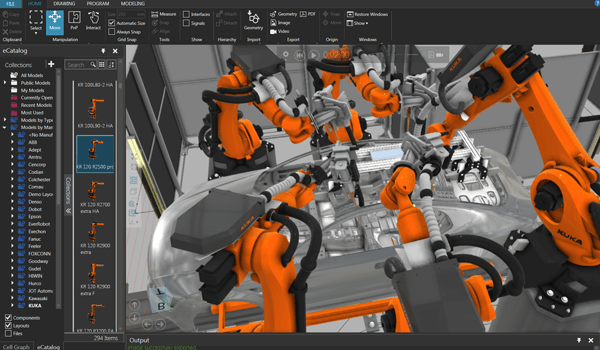

Virtual factory: Visual Components launches new version of its industrial design application

Visual Components has launched the latest version of its design application which the company says offers a number of new features and capabilities.

Visual Components 4.0 is the company’s new range of 3D factory simulation products, designed for manufacturing professionals and built on a “powerful, flexible, and scalable platform”.

The company says the new version offers:

- smarter simulation;

- improved user interface refresh;

- better performance;

- advanced rendering; and

- open architecture.

Visual Components was founded by a group of simulation experts with long experience in industry.

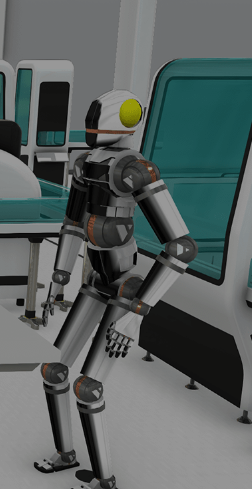

The software enables users to design and build an entire virtual factory, complete with detailed 3D simulated robotics and automation systems.

The company is promoting something it calls “virtual commissioning”, suggesting it is one of the best ways to save time and money.

“Commissioning, usually the last step in the engineering process, can take up to 15-20 per cent of the total delivery time of an automation system project,” the company says on its blog.

“Unfortunately, nearly 2/3 of the time spent in commissioning is spent on fixing software errors, since the control software usually goes through proper integration testing only after all the hardware has been procured and assembled.

“Virtual commissioning provides a solution for moving a significant portion of commissioning tasks to an earlier phase of the project, away from the critical path. In virtual commissioning, a simulation model of the system is created to replace the real factory.

“The virtual factory is then connected to the real control system, so that the simulation can be used simultaneously with the procurement and assembly to verify the design and test the control system. This allows for quicker detection of possible errors.”